- Additive Manufacturing

- Avionics

- Cabin Safety

- Certification Processes

- Classification

- Communication

- Continued Airworthiness

- Datalink

- EASA-FAA TIP rev 6

- Electrical systems

- Emergency evacuations

- International cooperation

- Lithium Batteries

- Lithium batteries (Non-rechargeable)

- Military - Dual Use applications

- Operational Suitability Data

- Oxygen systems

- Part 21

- Part 26

- Part-145

- SEPIAC

- Structures

Additive Manufacturing

Is it envisaged an EASA generic CRI to deal with this new technology?

As concise guidance material we have published the CM-S-008 on Additive Manufacturing. A generic CRI would have been a step before a CM publication.

Does EASA has a Group/Team who we can work to develop the processes to qualify additive manufacturing parts.

The appendix 1 of the CM-S-008 does contain a list of technical panel related contact points.

Isn’t there a difference between monolithic materials Vs sandwiched Composite materials?

Of course there is a difference. In terms of various manufacturing processes as well but when we consider it from its layer by layer build-up manufacturing process, it’s also an additive manufacturing process. This was the main intend of considerations within the presentation. For both composites (sandwich and monolithic) we have also clear interfaces between one and the next layers. Of course there is a strong difference in shear force capabilities which are mainly to be expected much lower for sandwich composites.

Do you consider Rapid Prototyping as Additive Manufacturing?

Rapid Prototyping is definitely additive manufacturing but it was actually just the beginning of this technology:

initially there was no concern on the statistical material properties. Rapid prototyping was being used for manufacturing of sophisticated moulds for castings or for non-critical non-loaded parts to fit into prototype designs. For serial parts production and also going from non-loaded to critical loaded parts, much more stringent requirements for material properties and manufacturing process stability will have to be fulfilled.

Avionics

ADS-B out: there are rumours saying ADS-B Out mandate could be postponed to 2025?

As a result of an assessment of a number of issues associated with the implementation of COMMISSION IMPLEMENTING REGULATION (EU) No 1207/2011 (known as the SPI regulation) the Agency proposed a number of possible rectifications, in particular a possible transition for aircraft until 2025. It must be noted that no proposal to change the basic date for the carriage of Mode S and ADS-B equipment with European Airspace as of 7 June 2020 has been made and as such this compliance date in force and applicable.

How can we identify the ops capability of the installed systems so that the operator can get the OPS SPEC amended with the capability? Identify RNP or PBN Doc.?

The AFM(S) proposed by the TC/STC holders should normally contain statements addressing the navigation operational capabilities demonstrated during the airworthiness approval.

FAA AC 20-138D Change 2, Appendix 5, provides some examples.

Is there an operational requirement which mandates Design Organisations to communicate the Performed Based Navigation (PBN) needs as well as all xxx.IDE technical requirements to the CAMO?

It is an essential requirement of the Basic Regulation that the Operators ensure the continued airworthiness of the aircraft and the serviceability of all the equipments required for the intended operation (be it Performed Based Navigation or anything else), as per Annex V point 6.1. It is also a responsibility of the Operators to ensure that, when maintenance is performed by a third party, it complies with all safety requirements applicable to the Operators (point 6.6). That includes communicating to the CAMO all the specific needs that may relate to PBN or any other operation being conducted.

Cabin Safety

Cabin safety: Where can we find samples of STC for zero-passenger cabin layouts?

EASA cannot disclose technical property information. EASA has approved several zero-passenger layouts from different applicants but data belong to the Approval Holders.

When do you plan to release CSXXX for smoke propagation and smoke penetration?

There will be no new Certification Specification but instead a Certification Memorandum (CM). The CM is in the final phase and please check the EASA CM webpage for status.

Covers replacement in 16g seats: is it required to perform certification tests to demonstrate compliance with 25.562?

EASA is accepting the guidance of FAA AC-25.562-1b; dress covers do not require normally dynamic testing. Cushion changes would at least require 14g downward testing.

Certification Processes

How to keep contact with EASA approved Production Organisations? What is expected from DOA on top of providing mail address and establishing a DO/PO agreement?

The DOA is expected to be in contact with the POA producing parts for the STC in case of multiple installations. Example could be metallic/composite structure for antenna installations.

It is obvious that the POA must inform the DOA in case of quality escapes etc. while the DOA must keep the POA informed if approved production drawings are changed.

What are the EASA minimum prerequisites for DOAs to process and approve minor design changes?

In order to be able to process and approve minor changes to the type design, the design organization must have at least the privileges 21.A.263 (c) 1 (classification) and 21.A.263 (c) 2 (approval of minors) in its TOA. It is fundamental that the aforementioned privileges are associated to the scope areas concerned by the minor changes.

Where can we find proper Form20 (Permit to Fly) and Form18 (Flight Conditions) templates?

Please refer to the already existing FAQ no. 20123 published on EASA for further information about Form 18 (a,b) and Form 20 (a,b).

Regarding where to find these forms:

Form 18a: Created by the design organisation

Form 18b: Available in the EASA Application Forms section

Form 20a: Provided by respective NAA

Form 20b: Created by the design organisation

When a Type Certificate holder refuses to share the pre mod approval data and we own the design & certification data, could we apply for an EASA STC once the aircraft is with operator?

The ownership of the aircraft is not directly impacting considerations whether an individual aircraft can or cannot be modified through an EASA change. The fact that the Design Organisation must assess the interfaces of their change with the pre-mod configuration as applicable applies in general. In some cases there is no alternative to a commercial agreement with the TC holder .

What can EASA do to improve consistency of STC timescales? - In my experience some have been very good but some appalling.

Each project is being consedered individually by the responsible product certification manager. While we try to keep a maximum reponse time of 4 weeks after the delivery of a technical package, we cannot avoid specific situations that might impact the overall timescale of the project.

STC configuration management practical approach: how to ensure a high level of customization maintaining an acceptable configuration control? Additional topic: impact on MMEL Suppl.

Several configurations can be covered by a single STC, provided that they are properly defined and identified in the design definition documents. Future customization should be updated in the design definition documents in accordance with an appropriate approval process. Aircraft serial numbers are not requested by EASA in the definition of the configuration.

MMEL supplements are constituents of the Operational Suitability Data.

Is EASA Policy for changes embedded in Non-EASA approved design applicable to minor changes? Example : Covers change of TSO C39 seats already installed by STC FAA.

The process used for installation of EASA changes in an aircraft including non-EASA approved designs is applicable to minor changes in the same way; please note that EASA would like to remind that the applicant is still expected to take all the efforts needed in order to define the interfaces between his design and the non-approved one.

Does the fact that general aviation and small CS25 aircraft are dealth with in one department induce any change to applicable regulations?

No.

To perform a Design it is needed to check the related Certification Specifications, Special conditions, Equivalent Safety Finding, deviations, annex to TCDS, any other document?

For compliance demonstration to the applicable certification basis there is also associated Guidance Materials & Acceptable Means of Compliance materials along with industry standards to be considered.

For questions outside of an STC project, does EASA have a preferred way for applicants to approach EASA experts?

Please send your questions to the STC coordinator using the generic mailbox STC_news [at] easa.europa.eu

Is there any method to open an STC application on a product not certified yet such as the A319 ACJ Neo?

Yes. It is acceptable to apply for an STC on an aircraft model not yet certified by EASA. However, the STC project cannot be closed before issuance of the Type Certificate.

Is it be possible to contact department coordinators directly for clarifications?

No. For questions no specifically related to STC projects, please send your query through the "contact us" form of our website. A contact person will then be defined (department coordinator if adequate) and will answer your question.

Will assigned PCM for the STC project stay in charge up to 5 years?

The PCM are assigned to projects as the result of multiple considerations. The Rotation policy is one of those considerations: it means that a given PCM is supposed to hand over the projects related to a specific aircraft type after a period of time that is in average 5 years

Rotation of PCMs: whilst understandable, how will EASA ensure that past agreements are not subject to renegotiation due to alternative view of the new PCM?

In case of discrepancy or lack of clarity, please ask for he involvement of the senior PCM who will ensure consistency with EASA policies.

Can you confirm that Panel's expert Statements of Satisfaction are submitted to DOA Team Leaders routinely; as I've not had this feedback from my DOATL (based in UK @ CAA Gatwick)?

Statements of Satisfaction are submitted to the Product Certification Manager not to the DOA Team Leader (DOA TL). The DOA TL has only access to the database where feedback is collected but not to the Statement of Satisfaction document itself.

Can we get feed back of DOA performance per project directly afterwards rather than waiting for it during an audit where the context is lost?

The DOA Dashboard including the Certification feedback is shared with the DOA only once per year (at time of the surveillance report). For project-related feedback, please contact the Product Certification Manager in charge of the certification project.

In my point of view, the important in the DOA dashboard is not to have a good or a bad notation, but to know why it is not 100%. It is important to progress.

Noted.

However, detailed information regarding the Certification feedback for the different projects are provided when the DOA signs the Memorandum of Understanding regarding the intended use of the data and just culture. Details about the MOU are provided by the responsible DOATL.

Is it also planned to have technical experts joining the audits with the DOA Team Leader to have more insight into the industry? We have good experiences with that.

To have Team Members from Certification participating in DOA Audits is the standard case if the volume and kind of design activities permit it. Some DOATLs have certification background and certain expertises in different field. In such a case, an expert may not be necessary in case the DOA performs only Minor Changes. However, with LOI implementation involvement of certification colleagues in DOA Audits will be more important.

Classification

If a piece of equipment similar to the G5 “Garmin electronic flight instrument ” is requested to be installed, how should the approval process be initiated?

If you are a design organization, please refer to the FAQ table of design change classification (for General Aviation only) to get guidelines in the decision process to classify an avionic design change as minor or major.

Question for the individual counselling event: My US colleagues have a FAA STC validated by EASA. Can I use a minor mod to extend the applicability?

No. The extension of the applicability should be requested through a Maj change to STC application by the FAA STC holder. Other possibility is that the EU DO, having good connection with US DO and availibility to data, could apply directly for an STC.

Part 21 classification: Is the replacement of each Commercial Off-The-Shelf (COTS) equipment currently at least a minor change?

There are two possible cases. The replacement of a COTS having the same Part Number (p/n) is considered a maintenance action. Should the p/n be different, it has to be considered as a change.

Communication

Is it possibile to set up a dedicated EASA website for STC (news, goodpractices, questions & answers...)?

No. The EASA Website has already a webpage dedicated to STC. Its contents will be updated as necessary.

Is there a list of attendees available for this conference? It would be very useful for networking if this was placed in the EASA welcome packs on the desks.

No, there is no publication intended.

Will EASA consider to publish all the asked question during the STC workshops in a booklet?

Yes, on the EASA Website

Please provide better access to „non-published“ Certification Review Items (CRI).

The Certification Review Items contents are considered as temporary material waiting to flow into final containers , such as Certification Specifications. The rulemaking roadmap for instance is incorporating regularly new CRI contents into the CS 25 yearly updates.

Continued Airworthiness

The Continuing Airworthiness Management Organisation (CAMO) has to evaluate the cumulative effect of many modifications. Does the DOA have to, therefore, provide the CAMO with Safety Assessment data?

The determination of a cumulative effect must be made within the justification of flight safety that is based upon the specific configuration. With that in mind, the CAMO will not evaluate the combined effect but rather assess conformity to the approved condition.

The applicant for a flight conditions approval may be asked to provide a safety assessment to the approving organisation.

When an STC is installed, the installer is obliged to determine possible incompatibilities of the intended installation with other design that may already be installed. In such cases, the CAMO may need to contact the DOA to get further advice or need approved changes to the installation instructions.

When did the community get information about the reported Continued Airworthiness occurrences recorded in the IORS tool? Without a summary of the reports, we will not have any positive impact to our design.

There is no publication for individual occurences.

This is about the benefit of the IORS tool to reporting organisation, e.g. when findings are made that affect multiple products and are independent from an individual occurrence for which the reporting organisation would receive feedback automatically.

Conclusions become visible to all when EASA issues Safety Information Bulletins about certain technical subjects.

If an STC holder determines that its modification does not affect FCBS (or create new FCS), there is no action per your presentation. Is there any data that is needed to be presented to EASA to obtain EASA's approval for the no action determination?

No. Subsequently, during an audit or if an operator or NAA identified one issue, something could come up and EASA would take action.

According to the EU regulation framework, design approval holders are responsible for the conduction of such evaluations.. Non-EU STCH located in the US should already hold compliant data for ageing aircraft regulation because of their compliance with CFR 14 under section 26.47. EASA can rely to a certain extent on these data and on a design approval holders to make their assessment correctly. However, STCHs should be conservative if they're not sure about the affect of an STC on FCBS.

Datalink

Datalink: is there a list of exemptions? Eurocontrol had promised this a long time ago.

The datalink equipage requirements as per the Commission Regulation (EC) No 29/2009 are applicable for operators starting from 5 February 2020 (CPDLC mandate) for all IFR GAT flight above FL285 within the airspace defined in the regulation. CPDLC in Europe is to be performed via ATN VDL Mode 2.

However, this regulation provides many criteria for non-applicability and/or exemptions.

It should be noted that the operator’s aircraft can benefit from the DLS equipage exemption, if the operator/aircraft satisfies one of the criteria listed in Article 3 (non-applicability) of the Regulation (EC) No 29/2009 as amended, or the aircraft type/model is listed as appropriate in the EC Decision for aircraft types/models to be DLS exempted (based on Article 14),

Please find below a link to a consolidated version of Regulation 29/2009 (not including the latest amendment 2019/1170)

https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1548919155226&uri=C….

Please find below the link to regulation 2019/1170, which revises mostly Article 3, thus introducing new possibilities for exemption (rather non-applicability):

https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32019R1170

In addition, there is a draft European Commission (EC) Decision on aircraft type/models to be DLS exempted (in accordance with Article 14), published for public consultation:

https://ec.europa.eu/info/law/better-regulation/initiatives/ares-2019-4…

Pending the comments review, the final EC Decision is expected to be published in October.

Datalink: 2020 target is real challenge for Operators, what are the possible derogations to this target date?

Please note that the Operators do not need to notify EASA of datalink exemption. EASA recommends the Operators to notify their Competent Authorities (from the country of registration). Also, EASA plans to issue an SIB (Safety Information Bulletin) to recommend the Operators to indicate their datalink exemption status in their flight plan.

EASA-FAA TIP rev 6

If the change to STC is Basic and does not require a change by the Certification Authority to STC, how does the operator/CAMO know the change is directly accepted?

As a matter of principle, when a Basic major design change does not affect the TC, TCDS, TCDSN, its approval by the CA (under provisions of TIP §3.3) is considered as a valid approval by the VA and will be accepted without any review and without any issuance of a VA approval.

In the specific case of STCs:

- If the Basic major change is brought by someone else than the STC holder, then it will trigger another STC (hence to be approved following the streamlined path)

- If the Basic major change is brought by the STC holder:

- If STC was revised to cover this change: to be approved following the streamlined path

- If there was no need to revise the STC: the mutual acceptance path (as per TIP §3.2) is applicable.

This is a very rare case where the major change to STC would be already covered by the documentation quoted on the STC certificate. This could be the case for an update of AML, update of ALS when no date is indicated on the certificate (ref. mention …”or later revisions of the above listed document(s) approved/accepted under the EASA system”).

In this very specific case, as for basic accepted design changes, the modality of approval by the CA serves as “proof”/indication that the change is directly accepted.

It is in the interest of the design approval holder to maintain a clear status of the nature of its changes approvals (validated or not, basic or non-basic). In case of doubt, confirmation should be sought from the CA.

Can a US manufacturing organisation use an EASA minor change as the means to apply to the FAA for a 'Request for Conformity'& permit release of parts on a 8130-3?

The FAA has launched an exemption process for extending the scope of approval of manufacturing organisation to the production of design approved by EASA only

Are there FAA fees to pay for STC validation?

The FAA does not charge any fee for validation

EASA/FAA Bilateral agreement Technical Implementation Procedures: Does EASA and FAA intend to improve the required 15 working days just for issuance of the approval which in worst case keeps the prototype aircraft on ground?

The 15 working days are not prescriptive, they indicate the maximum period of time for streamlined validation.

In case technical review is needed, adequate time for investigation has to be considered.

EASA/FAA Bilateral agreement Technical Implementation Procedures:The 15 days as timeline for the streamlined validation is far beyond reality! Is your statement based on own experience? The same question for Non-Basic validations with the 90 days timeline.

The 15 days have to be considered upon the receipt of the complete data package for a streamlined validation. There is no commitment for Non-basic validations to complete the evaluation and issue consequent approval in the time of 90 days.

EASA/FAA Bilateral agreement Technical Implementation Procedures: About the Validation Authority process, should the demonstration of FAA compliance (CS/FAR) be systematically provided by the applicant ? or not needed because checked by EASA?

The demonstration of compliance and related applicant's declaration of compliance have to be provided by the applicant. EASA can release the statement of compliance upon being provided with the above elements. The applicant should perform the compliance demonstration activity without being requested by EASA.

Are minor changes automatically accepted by both authorities (EASA and FAA) independently if they were designed by Designated Engineering Representative (US DER) or EASA Approved Design Organisations (DOA), independently from the registry of the aircraft?

Yes, it is possible. Minor changes covered by TIP §2.2.1/2.3.1 and TIP §3.2.2 are eligible to automatic acceptance by both authorities, independently of the registry of the aircraft and independently of whether they were designed by US DERs or DOAs.

However, as per the terms of the Bilateral Aviation Safety Agreement between US and Europe, the automatic acceptance is only applicable when the design approval is granted to an applicant located within the territory of US or the European Union.

Are minor repairs treated as the same as minor changes between FAA and EASA?

Minor repairs covered by TIP §2.2.2/2.3.2 are eligible to automatic acceptance by both authorities. In principle they are treated the same way as minor changes, although for a minor repair the applicant does not have to show compliance with the Validation Authority certification basis.

It seems that EASA PCMs prefer to close EASA type investigation before the involving of FAA for validation purpose.

Concurrent validation as per TIP rev 6 is only accepted for Non-basic design changes. Concurrent validation principles are expressed in TIP rev 6 para 3.5.7.3.

Can an EASA Design Organization use Designated Engineering Representative (DER) approved minor changes with no EASA involvement?

Yes, when covered by TIP §2.3.1, DER approved minor changes issued to US design holders are automatically accepted by EASA.

One of our customers is not accepting an EASA minor change to FAA STC on an Airbus Aircraft. They need the FAA STC to be validated by EASA first. What’s your opinion?

The minor changes are considered changes to the aircraft and there is no formal link to the STC. Therefore the FAA STC does not need to be validated by EASA.

Emergency evacuations

Regarding emergency evacuation, do you think safe and normal the policy of low cost company that separates wife and husband or family and kids older than 12?

EASA is not aware of any policies that forecast intentional separation of kids and parents in commercial aviation. Beyond this statement, specific policies for special categories of passengers fall into the remit of EASA Air Operation regulations.

If experience shows that passengers are evacuating with carry-on items, why not creating a requirement to implement an auto-lock of the overhead storage?

This option was investigated and considered among several options but not deemed as the preferred one. This option might lead to even extra delay time due to passengers trying to force the overhead storage. One option might be to directly separate the passengers from their baggages, by placing all baggages in the cargo compartment, for instance.

International cooperation

Regarding EASA/FAA TIP rev 6: classifying a change as major or minor. Whose classification is this - the Certifying Authority or the Validating Authority, since the classification procedures differ?

Classification is the Certifying Authority (CA) responsibility and must be accepted by the Validating Authority (VA) .

The applicant shall classify the change (minor/major) according to the applicable regulatory framework for its design organization. This means that a DOA (EU) shall classify changes according to EU 748/2012 Annex 1 (Part 21).

Lithium Batteries

What is the EASA position on Lithium batteries installed as "loose parts"? For example Lithium batteries installed in portable In-Flight Entertainment systems (with multiple cells 100Wh) ?

Loose parts are addressed by EASA SIB 2016/08. In the SIB, the Agency reminds operators of the need to obtain from their competent authority an authorisation when the limits are exceeded. To calculate the limits, the SIB establishes that the addition of Wh of all the batteries powering the device should be considered instead of that of each individual battery.

Can an electric wheelchair in the cabin be treated as a Portable Electronic Devices (PED)? If not how could the battery system be managed to ensure safety during flight?

Regulations on the transport of dangerous goods by passengers and crew, including mobility aids, medical equipment and PEDs, are contained in Part 8 of ICAO Doc. 9284 Technical Instructions for the Safe Transport of Dangerous Goods by Air. However, airlines may impose further restrictions for safety reasons. Therefore, it is advised to consult the Dangerous goods information provided by the airline before flying.

Lithium Battery: How many cases where investigated to conclude that the traditional practices were inefficient? No Airworthiness Directive known to correct interference issue on in service aircraft. (ref. to Electrical System updates presentation)

This was the conclusion of the working group EUROCAE WG-31 and SAE AE-4. Please refer to ED-248 section 4.2

Lithium Battery: When is CS-25 be expected to be updated to reflect different types of energy storage devices (Lithium technology, Fuel Cells etc.)?

This is a planned rulemaking task with no fix date yet, due to the recent/on-going publication of the qualification standards and ETSOs. When the topic is considered mature enough to publish requirements and Acceptable Means of Compliance the rulemaking task will be started.

Minimum Operational Performance Standards for non-rechargeable Lithium Batteries: DO-227 and other referenced standards are applicable to permanently installed equipment. Is there any mandatory requirement for “carry-on” medical equipment?

Carry on medical equipment is regulated by operational rules, not certified as part of the aircraft. Regulations on the transport of dangerous goods by passengers and crew, including mobility aids, medical equipment and PEDs, are contained in Part 8 of ICAO Doc. 9284 Technical Instructions for the Safe Transport of Dangerous Goods by Air. However, airlines may impose further restrictions for safety reasons. Therefore, it is advised to consult the Dangerous goods information provided by the airline before flying.

Lithium Batteries: How many incidents with Lithium Batteries have been recognised in the past year. Are Lithium Batteries still dangerous?

There have been some significant incidents in the last year that show that Lithium battery technology poses a hazard for the aircraft.

Lithium Battery: Will EASA mandate actions against existing designs?

EASA is currently gathering information about existing installations and working with FAA to determine the potentially existing hazardous cases. The need to mandate actions against some specific designs is still under review and no decision has been taken yet.

In case of specific incidents, EASA is already issuing Airworthiness Directives to improve some current installations in a case by case basis.

How do we control the Lithium batteries in all smart phones and other devices?

Portable Electronic Devices are regulated by operational rules. Please refer to: https://ad.easa.europa.eu/ad/2017-04R1. More info can be found here: https://www.iata.org/whatwedo/cargo/dgr/Documents/passenger-lithium-bat…

is EASA having in service occurences linked to Lithium batteries installed within Cockpit Voice Recorder and Flight Data Recorders current 30 days Underwater Locator Device (ULD) ?

Many Lithium batteries are being introduced because of the 90 days requirement for the ULD. The risks associated to Lithium batteries is not dependant on the equipment where it is installed, but to the chemistry of the battery, which is highly explosive and flammable.

Will EASA issue an Airworthiness Directive to replace all Emergency Locator Transmitters and Underwater Locator Devices currently installed, if TSO/ ETSO standards are not acceptable to EASA?

No action/initiative (in coordination with FAA) was taken so far.

It is good that the DO community is made aware about the Lithium Battery Special Conditions. Design Organisations not aware of those might wrongly classify the design changes including a Lithium battery.

agreed

Lithium battery: Is there any generic Certification Review Item issued?

Yes, please check the EASA website for the applicable Special Conditions.

For a particular aircraft please verify on the associated Type Certificate Data Sheet.

Why does the current Special Conditions CRI for non rechargeable batteries not explicitly state that it would be applicable to Batteries which were qualified to the ETSO C142 Standard?

Previous Means of Compliance proposed:

Due to missing a more appropriate standard, ETSO C-142a + Risk assessment at A/C level was an acceptable MoC to the SC contained in the CRI.

Current Means of Compliance proposed:

Minimum Operational Performance Standards (MOPS) for Non–Rechargeable Lithium Batteries DO-227A/ETSO C-142b + risk assessment at A/C level (limited to Special Conditions 3, 4, 5 & 6) is an acceptable MoC to the Special Conditions 1 to 6 contained in this CRI.

ETSO C-142b referring DO-227A material was published in 2020.

What is the EASA approach for rechargeable lithium batteries installation on aircraft types other than CS-25?

The same policy is currently applicable to CS-25 aircraft types applies also to CS-29, CS-23 level 4, and CS-27 Cat A aircraft types. For CS-23 levels 1, 2, and 3 and for CS-27 non-CAT A, EASA will evaluate the need for using the same approach on a case-by-case basis, based on the risk that the installation could pose to aircraft safety.

When validation with foreign authorities would be envisaged, EASA recommends checking potential means of compliance discrepancies related to lithium batteries.

Lithium batteries (Non-rechargeable)

I plan to install a non-rechargeable Lithium battery (NRLB) with capacity under 2 Wh. How should I classify my project?

When the battery is qualified against UL1642 standard, the project can be classified as minor. Otherwise project should be classified as major.

I plan to relocate an equipment powered by a non-rechargeable lithium battery (NRLB) but the pre-mod configuration was designed by another design organization. Under which conditions am I allowed to classify the design change as minor?

The evaluation of the original safety assessment issued to justify the installation of the pre-mod configuration is a prerequisite to proceed with a minor classification. When the original safety assessment is not available, the non-rechargeable lithium battery (NRLB) relocation project should be classified as major.

What is the intent of Note 2 included in the non-rechargeable Lithium batteries (NRLBs) Special Condition’s published the 7th of April 2021 in EASA website?

Note 2 - included in the non-rechargeable Lithium batteries (NRLBs) Special Condition’s of 7th of April 2021- has the intent to allow applicants to substantially increase the level of fire safety of already approved NRLB installations without the need to demonstrate compliance with the special conditions.

Based on "Note 2", the special conditions are not applicable to changes to previously certified non-rechargeable lithium battery installations where the only change is either cosmetic or to relocate the installation to improve the safety of the airplane and occupants. A cosmetic change is a change in appearance only, and does not change any function or safety characteristic of the battery installation. The special conditions are also not applicable to unchanged, previously certified non-rechargeable lithium battery installations that are affected by a change in a manner that improves the safety of its installation. The above exceptions are limited to changes/relocations to baseline aircraft installations approved for certification projects for which the special condition was not applicable.

EASA has determined that allowing the above exceptions is in the public interest because the need to meet all of the special conditions might otherwise deter design changes that may substantially improve safety.

Here an extract of the Special Condition document:

Note 2: These special conditions apply in lieu of 25.1353(c)(1) through (c)(4) to non-rechargeable lithium battery installations as follows:

• To all changed installation (new battery part number or new environment) except if the design change can be considered cosmetic. A cosmetic change is a change in appearance only and does not change any function or safety characteristic of the battery installation.

• To all relocated lithium batteries, except if the relocation is demonstrated to improve the safety of the aeroplane and of the occupants, leading to a change that provides a substantial fire safety improvement.

• To all existing non-rechargeable lithium battery installations affected by a design change, even if the battery or battery installation itself does not change.(e.g. change in ambient temperature or pressure environment in which the battery operates, change on the electrical load on a battery). Except if the design change improves the safety of the non-rechargeable lithium battery installation.

Applicants, who intend to justify that this Special Condition is not applicable, shall generate the evidence that the proposed design meets the above criteria in this note 2. This evidence shall include a detailed assessment of the battery installation on the baseline aircraft and the improvement due to the proposed change considering a battery thermal runaway failure for both installations.

The assessment should:

• Consider the battery thermal runaway effects of heat, explosive energy, projecting debris and toxic gases.

• Address the proximity of the battery to occupants, critical systems and equipment, structure, and any other installations that could be a hazard if exposed to a battery thermal runaway (e.g., oxygen bottles/lines, fuel lines).

The above exceptions are limited to changes/relocations to baseline aircraft installations approved for certification projects for which the special condition was not applicable.

CS 25.1353(c)(1) through (c)(4) remains in effect for other battery installations.

When a non-rechargeable lithium battery (NRLB) project is classified as major, how is EASA going to establish the level of involvement (LOI) in the certification project?

General EASA guidance on Level of Involvement (LOI) applies (ref. CM-21.A/21.B-001 Issue 2). Complexity of the project, Applicant Capabilities and past experience with NRLB installation projects should be taken into account to define the EASA LOI in the project.

If I have a non-rechargeable lithium battery (NRLB) specific case not fitting to the 4 cases where a direct minor classification is allowed, and I consider that severity of a thermal runaway failure can be considered less than hazardous, can I ask to EASA to re-classify one specific project?

Yes, according to Part 21 „When the strict application of the paragraph 3.3 criteria from GM 21A.91 Classification of changes to a type Design results in a major classification, the applicant may request re-classification, if justified, and Agency could take the responsibility in re-classifying the change.”

Does EASA consider the installation of an equipment powered by a non-rechargeable lithium battery (NRLB) with an ETSO authorization compliant with the special conditions without further evaluation?

No, the ETSO authorization does not constitute a means of compliance with all the special conditions. In all cases installation aspects shall be taken into account and an assessment of the level of safety of the non-rechargeable lithium battery (NRLB) installation on the aircraft shall be generated, e.g. zonal safety analysis, etc..

How should I classify a change when my non-rechargeable lithium batteries (NRLBs) installation does not fit any of the 4 cases applicable as minor change under DOA privileges?

Other installations of non-rechargeable lithium batteries (NRLBs) would be classified as MAJOR. Here are some examples of design changes that should be classified as major changes:

Example A

Installation not subject to SC-F25.1353-01 (Special Condition final version published in EASA website on 7th April 2021), when a substantial fire safety improvement is demonstrated based on Note 2 of the special conditions.

Rationale for MAJOR classification

The evidence that a substantial fire safety improvement is achieved through the relocation of a NRLB shall be discussed and agreed with EASA.

Example B

The design change introduces an exposed installation of a NRLB, even if the battery meets ETSO-C142b (e.g. ELT installed on a bulkhead in the passenger cabin).

Rationale for MAJOR classification

Despite meeting the minimum performance standards of ETSO C142b provides a higher level of safety, excluding fire and explosions and requesting equipment skin temperatures under 204° C, ejection of gases from the venting provisions included in the battery design is allowed. Quantity, composition and temperature of vented gases are reportable items during ETSO approval and shall be evaluated during installation. DO-227A explains that the hazardous emissions may be flammable, explosive, corrosive or toxic in sufficient concentrations. DO-227A recommends the installer to work with the battery manufacturer to quantify and mitigate the effects of hazardous emissions based on venting capabilities of the battery system and air movement and exchange characteristics at the installed location.

Example C

The design change consists in the installation of a NRLB in the cockpit, even if the battery meets ETSO C-142b.

Rationale for MAJOR classification

The same considerations applicable to example B are valid also for example C. Furthermore, the direct exposure of flight crew members to the effects of a lithium battery thermal runaway event is considered particularly critical.

Example D

The design change consists in the installation of a NRLB in inaccessible areas*, even if the battery meets ETSO-C142b.

*An inaccessible area is an area that can be accessed only after the removal of panels , or is not readily reachable by a person with the contents of a hand-held fire extinguisher. These areas tend to be behind interior panels (such as sidewalls or ceilings), or areas below the passenger floor.

Rationale for MAJOR classification

The same considerations applicable to example B are valid also for example D. Furthermore, the installation of a NRLB in an inaccessible area does not allow crew members to perform effective fire-fighting.

Which are the 4 cases involving non-rechargeable lithium batteries (NRLBs) agreed by EASA to be classified as minor change under DOA privileges?

Direct minor classifications (4 Cases):

- Battery with Capacity up to 100Wh AND installed in the cabin in a fully enclosed area where the occupants can visually localize it in case of fumes or fire AND no oxygen lines/equipment, water, fuel or any other flammable substances in the same enclosure AND battery qualified at least to ETSO-C142b.

- Modifications involving the installation of a Lithium battery within an equipment with a capacity up to 5Wh AND ETSO 142b AND no other reasons to classify the change as Major.

- Relocation of equipment containing a battery with ETSO C142b authorisation and with no impact in the original Safety Assessment AND conditions of installation not worse than the original ones (in terms of separation to oxygen lines/equipment, water, fuel, other flammable substances, heat points).

- Project requesting exemptions to Special Condition as per Note 2 on Special Conditions’ final version published in EASA website on 7th April 2021 are limited to cosmetic changes.

NOTE: Changes expected to demonstrate substantial fire safety improvement as per Note 2 are considered as MAJOR.

Is the previous approach for minor/major classification presented in STC workshop 2019 still valid for non-rechargeable lithium batteries (NRLBs)?

No, it is superseded. Some types of design changes previously eligible for reclassification as minor will have to be classified as major. The new approach applies to projects starting on or after 1st January 2022.

What is the EASA approach for non-rechargeable lithium batteries (NRLB) installation on aircraft types other than CS-25?

The same policy is currently applicable to CS-25 aircraft types applies also to CS-29, CS-23 level 4, and CS-27 Cat A aircraft types. For CS-23 levels 1, 2, and 3 and for CS-27 non-CAT A, EASA will evaluate the need for using the same approach on a case-by-case basis, based on the risk that the installation could pose to aircraft safety.

When validation with foreign authorities would be envisaged, EASA recommends checking potential means of compliance discrepancies related to lithium batteries.

Has EASA released Special Conditions on non-rechargeable lithium batteries (NRLBs) installation for all CS-25 aircraft types?

The TCDS of the vast majority of CS-25 aircraft includes special conditions on non- rechargeable lithium batteries (NRLBs) installation. Just a few models remain for which special conditions have not been released. If your project applies to one of those models, please contact EASA.

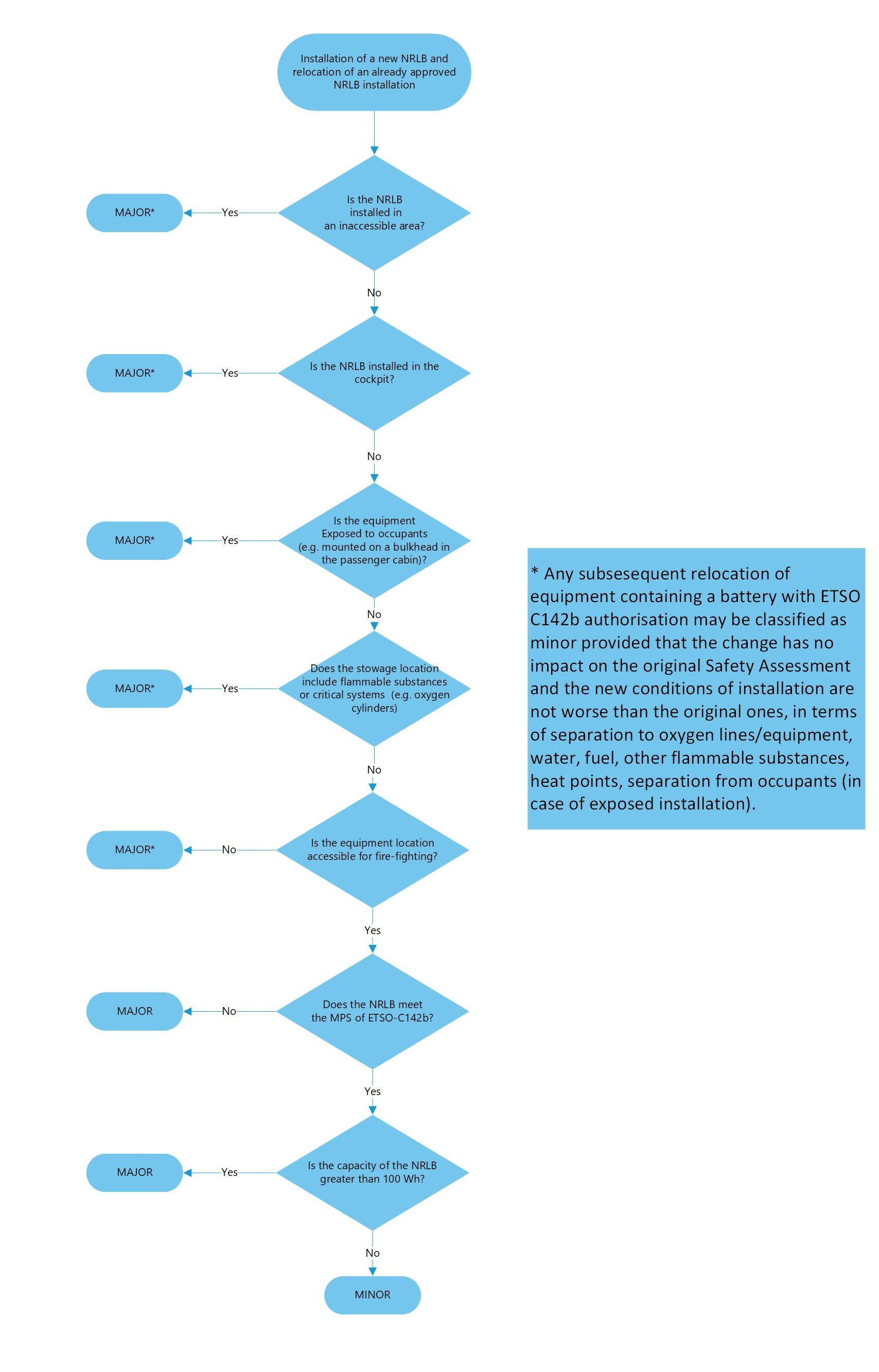

Is there a flowchart helping on the minor/major classification of projects involving non-rechargeable lithium batteries (NRLB)?

Yes, see the following “Non rechargeable Lithium batteries installation minor/Major classification flowchart”

What is EASA’s plan on non-rechargeable lithium batteries (NRLB) regarding qualification and means of compliance (MoC) with the NRLB Special Conditions?

EASA intends that every single non/rechargeable lithium battery (NRLB) installation shall be compliant with ETSO C142b or that any installation has to assure qualification level according to MOPS DO-227A or later standards for any project with a date of application after 30 June 2025.

The entry into force date is based on the safety gain resulting from the installation of NRLBs meeting this MOPS DO-227A standard (and ff.) and the availability of ETSO C142b/DO-227A equipment.

This decision leads to means of compliance (MoC) based on the installation of ETSO C142a/MOPS DO-227 equipment complemented with a risk assessment at A/C level, as MoC with the Special Conditions applicable to NRLB Installations (ref. SC-F25.1353-01) will not be accepted after 30 June 2025.

Operational Suitability Data

Can a "Nice to have" Operational Suitability Data change be classified as Major ? If yes, do you have an example ?

The “nice to have” OSD changes, often referred to as stand-alone changes need to be classified as any other changes to the type certificate, as part of the certification process. The guidance provided in Part-21 GM to 21.A.91 paragraph 3.5 provides additional details regarding classification criteria for the various OSD constituents.

How should an STC holder handle TC holder (TCH) MMEL rework to remove TGL26 "As required by regulation" impacting the CS-MMEL?

Items covered in the TCH MMEL reflect the configuration installed on the aircraft by the TCH and may be updated through revisions process. In particular, to retain the level of relief on some items previously indicated as “As required by regulations” in the JAA/EASA MMELs, TCH have updated their OSD MMEL.

GM to ORO.MLR.105 indicates the Operators are allowed to use the CS-MMEL guidance only if no OSD MMEL exists for the aircraft type. Should the level of relief not be applicable to the STC installation applied for approval to EASA after 19 December 2016, the STC holder should address the necessary changes to the OSD MMEL through a supplement creation or update

Cabin Crew Data (CCD) related to VIP interior (such as Boeing Business Jet): is EASA expectation that it would be a VARIANT? It seems logical however the Aircraft Difference Table (ADT) questions would lean towards NEW TYPE.

Within the OSD-CCD technical investigations, the use of the ADT serves the following purposes:

-identify the differences between the “baseline” aircraft and the “candidate”, in order to establish the Cabin Crew Data that needs to be provided by the applicant as basis for the operator to develop their customized Cabin Crew training, to be approved by the Competent Authority (CA);

-establish the status of “new type” or “variant” for the “candidate”, by assessing the identified differences in light of the appropriate “Difference Levels”( see Difference Levels as defined in OSD-CCD);

- determine the classification of the change to CCD as “minor” or “major” (see GM 21.A.91 §3.5. c).

Whether it applies to the VIP or to airline-type configurations, a change to the CCD will render the “candidate” aircraft as a “variant” (with 3 Levels of complexity regarding Cabin Crew associated training), or, as a “new type”, if Level 4 applies.

“Same aircraft” applies when the design change involves stretched fuselage and the only CCD change resides with increased numbers of cabin occupants/PSU/etc. Its associated Difference Level is Level 1.

Part 21

How will the Agency notify the acceptance of the certification basis?

It could be made in different ways depending on the size of the project, the forms used by the applicant and other circumstances. In general, any traceable way is acceptable (e.g. emails, formal letters, specific CAI etc). In the future SEPIAC will have a feature to trace this acceptance.

Is there a maximum timeframe considered for EASA to accept a Certification Program and further for the acceptance or adjustment to the Level Of Involvement proposed by the DOA?

There is no maximum timeframe for EASA to accept a Certification Program and notify its LOI, nor to update it on the basis of new information impacting the risk previously assessed. Nevertheless, the Agency is committed to reduce this timeframe as much as possible: we strive to review documents (including certification plans) within 30 days, which we achieve on average. (ref also to ‘Code of good administrative practice for the staff of the EASA in their relations with the public’, ED Decision 2009/078/E).

Is it not possible to consider the number of Compliance Demonstration Items (CDIs) as a criterion before starting with Level Of Involvement . For instance projects with less than twenty CDIs. Should the CDI list be defined and sent to EASA?

No, the EASA LOI decision has to be based on a risk-assessment and the number of CDIs does not have a direct influence on the risk. Additionally, the number of CDIs could be very small (e.g. containing a single document) or very large (e.g. containing the whole project) depending on the approach selected by the applicant.

How will the privilege of submitting compliance documents without further involvement be modified by the Level Of Involvement process?

The point 21.A.263 (b) will be cancelled by the next amendment to Part-21 (ref to Opinion 07/2016).

According to the new concept, any application for major change/repair, STC, APU ETSO or TC submitted to the Agency shall be complemented by a risk-assessment and a LOI proposal prepared by the applicant. After acceptance of the Certification Program/LOI, data and activities not included in the EASA LOI will be accepted without further verification.

Regarding the tests, is it possible to submit only the plans and have the report validated by the Compliance Verification Engineer without EASA checking if all the tests are "passed"?

The test reports shall be submitted to the Agency only if they have been retained as part of the EASA LOI.

Nevertheless, regardless of the LOI determination, it must be noted that the amended Part-21 will contain a new provision requiring applicants to inform the Agency in case of unexpected difficulties encountered during demonstration of compliance (ref to Opinion 07/2016 point 21.A.20(b)):

a significant failure or finding resulting from the tests performed as per points 21.A.33 or 21.A.35 is to be notified to the Agency.

The Level Of Involvement risk analysis is a transfer of the Agency workload. Could applicants expect to have a reduction of the STC fees in the future ?

The risk-assessment to be performed in order to propose an LOI is not a transfer of Agency workload and in consequence no reduction of STC fees is expected.

Has the Level Of Involvement definition for an STC a direct impact on the STC fees?

No, the new LOI concept does not have an impact on the fees.

Is the overall DOA performance indicator based on feedback of DOA Teamleader and Product Certification Manager? Panel feedback per panel, or on average?

The overall DOA performance takes into account feedback from DOA TLs (surveillance activities), PCMs and experts (projects).

The performance at panel level mainly takes into account feedback from PCMs and experts. Additionally, DOA TLs feedback can also be considered for performance at panel level.

The Agency is currently working on an evolution of the DOA performance system.

What is the minimum amount of 'DOA Holder Performance' to not be always at the bottom of the scale in the matrix?

To obtain a higher DOA performance, the applicant should strive to obtain a higher rating by EASA experts and PCMs during certification projects considering:

Project planning and communication

Applicable requirements and means of compliance

Compliance documents

If the DOA is newly established, or in the case of a very low number of applications submitted to EASA, the DOA performance will be assessed as unknown/low.

Do we have to document the justification of the Level Of Involvement selection and submit it with the Certification Program to EASA as a supporting document?

The applicant is requested to provide a proposal for the risk assessment of all the CDIs as part of the Certification Program. Where not obvious or where the applicant thinks it is necessary to explain the proposal, a justification should be submitted.

Each DOA has the freedom to select the most adequate physical document structure for the certification program which, has to consist of the points listed under 21.A.15(b).

The aircraft manufacturers do not take into consideration customized configurations when issuing documentation (such as Service Bulletin). What is EASA policy in order to cope with this issue?

In order to perform any change, the STC applicant shall identify the configuration of the aircraft to be changed as per Part 21.A.101 along with the associated certification basis. It is worth to remind that 'Prior to installation of this change/repair it must be determined that the interrelationship between this change/repair and any other previously installed change and/ or repair will introduce no adverse effect upon the airworthiness of the product.'

What is the validity of a Non Technical Objection (NTO) statement from Airworthiness point of view?

NTOs are usually used in the context of Flight Condition approval process. Nevertheless, if there is a connection between two organisations that are concurring on the same topic, the primary Design Organisation could issue an NTO to confirm that there is no safety impact on the existing design. In that case the NTO will support the compliance demonstration without constituting in itself a Means of Compliance. The responsibility of the new design relies ultimately on the Applicant.

Part 21: Will be a dedicated qualification needed to perform the risk assessment associated to the Level of Involvement proposal?

No. There are no specific requirements for the qualification of persons that perform the risk assessment in Part-21. The company has to ensure as part of their procedures and training provisions that competent persons with sufficient experience perform the tasks they are assigned for within their DO

What is the expected benefit when the new Level Of Involvement concept is implemented in Part 21 and a low to very low involvement of EASA is agreed on a project?

The associated involvement corresponds to focus of the Agency on elements of projects where the risk of a non-compliance is higher.

Part 26

Does Part 26 apply also to Non Commercial Carrier operators? (ref. to AIR OPS regulation)

Each point (requirement) in Part-26 specifies who is affected by the requirement. Today most of the requirements concern operators of large aeroplanes used in commercial air transport. However, certain requirements can also affect large aeroplanes, and this independently of the type of operation. It is for instance the case for point 26.400 on fire extinguishers, introduced with Commission Implementing Regulation (EU) 2019/133.

Some requirements can also affect Large helicopter.

Part-145

How did you install a Commercial Off-The-Shelf (COTS) equipment without EASA form-1? How do you arrange Part-145 side actually?

Note: The following information refers to the applicable rules, as amended with Commission Delegated Regulation (EU) 2021/699 and Commission Implementing Regulation (EU) 2021/700, which introduced more possibilities for installation of new parts. Due to the implementation period granted with these rules, the referenced paragraphs below will only be applicable as from 18 May 2022. Refer to these rules for the applicability dates.

The main idea is that to install new parts (by organisations approved i.a.w. Part-145, Part M-F or Part-CAO or by the individuals permitted to do maintenance in accordance with Commission Regulation (EU) No 1321/2014), the new part has to be accompanied with an EASA Form 1. However, M.A.502, 145.A.42 and ML.A.502 of Commission Regulation (EU) 1321/2014 permit certain alleviations by referring to 21.A.307 of Commission Regulation (EU) 748/2012. In particular, point (b) of 21.A.307 permits the installation of:

- 21.A.307 (b)(2) - Certain parts in ELA1 and ELA2 aircraft under the responsibility of the aircraft owner. (These parts were already permitted for installation prior to adoption of Commission Delegated Regulation EU) 2021/699 under the old reference 21.A.307(c))

- 21.A.307(b)(3) and (b)(4) – certain parts that the design approval holder (e.g. TC holder) or EASA in CS-STAN have determined as fulfilling certain conditions and are accompanied with an equivalent document that contains certain relevant information. A video explaining in detail why and how Part 21 was changed is available on the 2021/699 rule page under “Related content”.

Some of the COTs equipment may benefit from the above alleviations. Refer to the relevant text of the rule for full details, including the specific conditions to be fulfilled by 21.A.307 (b) parts, the need for the parts to be in a satisfactory condition, required info in the equivalent document, and parts marking.

In addition to the above, standard parts and consumables are exempted from the need to be accompanied with an EASA Form 1. Also, international safety agreements signed between the EU and a third country may alleviate the need of an EASA Form1 by recognising as equivalent a certificate issued under the third country rules. Refer to the relevant bilateral agreements and related implementation guides for full details.

Refer to Commission Regulation (EU) No 1321/2014 for the maintenance of parts referred in 21.A.307(b).

SEPIAC

For applicants, it is difficult to see which documents have been uploaded, reviewed or validated by the Product Certification Manager or EASA panel experts. Sepiac is a good idea but needs improvements

Sharepoint offers the “Alerting systems” where every user can set-up notifications on files or libraries. In addition, the status metadata provide an indication of the review status and the new Project dashboard introduced with Release 2 allows users to see the global status panel by panel. Future releases will introduce Workflows which would allow a more punctual review/approval status for documents.

Who is responsible for closing the project in SEPIAC?

The EASA PCM makes the decision to close the project. The technical closure is performed after communication with the PCM by the SEPIAC team

Please can you advise where and when DOA training on SEPIAC will be held?

Currently we have no regular training sessions scheduled, nevertheless any Applicant can request via their PCM or functional mailbox (sepiac-support [at] easa.europa.eu ) a dedicated training (stating that SEPIAC does not cover specific Design Organisation Approval processes). We can then schedule it onsite, at EASA or by Webex according to the Applicant needs. If we start to receive many request we could think for the future to schedule some regular sessions.

Sepiac is not used or misused by a lot of EASA PCM and experts. Today we have to use both Sepiac and e-mail. It is really inefficient and time consuming!

We can work to improve the platform, provide support and information to all the users… but unfortunately not make it mandatory for people to use the tool in a certain way.

What is the intention of EASA regarding the communication channel to be used in the framework of certification projects? Shall all the communication be done via Sepiac? Or will Sepiac and e-mail be there?

When a project is managed in SEPIAC, all the related communications that are worthy of being recorded should be managed in SEPIAC. This does not prohibit to use email for all other kind of communications such as organization and planning of meetings.

Structures

Structures requirement: cabin loading for occupant safety. Type Certificate Holder specification remain acceptable for demonstration of compliance, however these spec ifications are not made available by EASA?

Cabin loading limitations for a specific aircraft model is considered as Aircraft Manufacturer proprietary information and such data cannot be made available by EASA. In accordance with Part 21, an applicant can either obtain this information through an arrangement with the Aircraft Manufacturer, or through its own resources, for example by reverse engineering based on existing and approved cabin layouts for which sufficient data is available to perform such an assessment.

Are Cabin Loads applicable for cockpit installations as well?

Cabin loads are understood to include inertia loads resulting from emergency landing conditions as well as flight and ground loads conditions. These type of loads also need to be considered for cockpit installations.