"Ensuring that aircraft are ready and that you have the right tools, equipment and infrastructure in place"

People need things (i.e. infrastructure, equipment and tools) to be effective; there are lots of resources that people, and the wider organisation, use to carry out its purpose.

The most basic resource is the aircraft itself, which must be airworthy and maintained for operations. Depending on the aircraft you operate and what type of operations you perform, are you fully aware of what future technologies are required for safe operations?

There are a wide range of other resources that your operation relies on. This includes (but are not limited to): tools (including IT systems), equipment (like vehicles and ground equipment) and infrastructure (such as buildings, facilities and the airport or control tower or centre). All of these resources must be fit for purpose, maintained and cared for.

An infrastructure for safe operations starts at the very beginning, with the people and mindset of the organisation. Education and skills are necessary. Then, in compliance with regulations and procedures, there must be processes in place for understanding, learn from; and be proactive against risk.

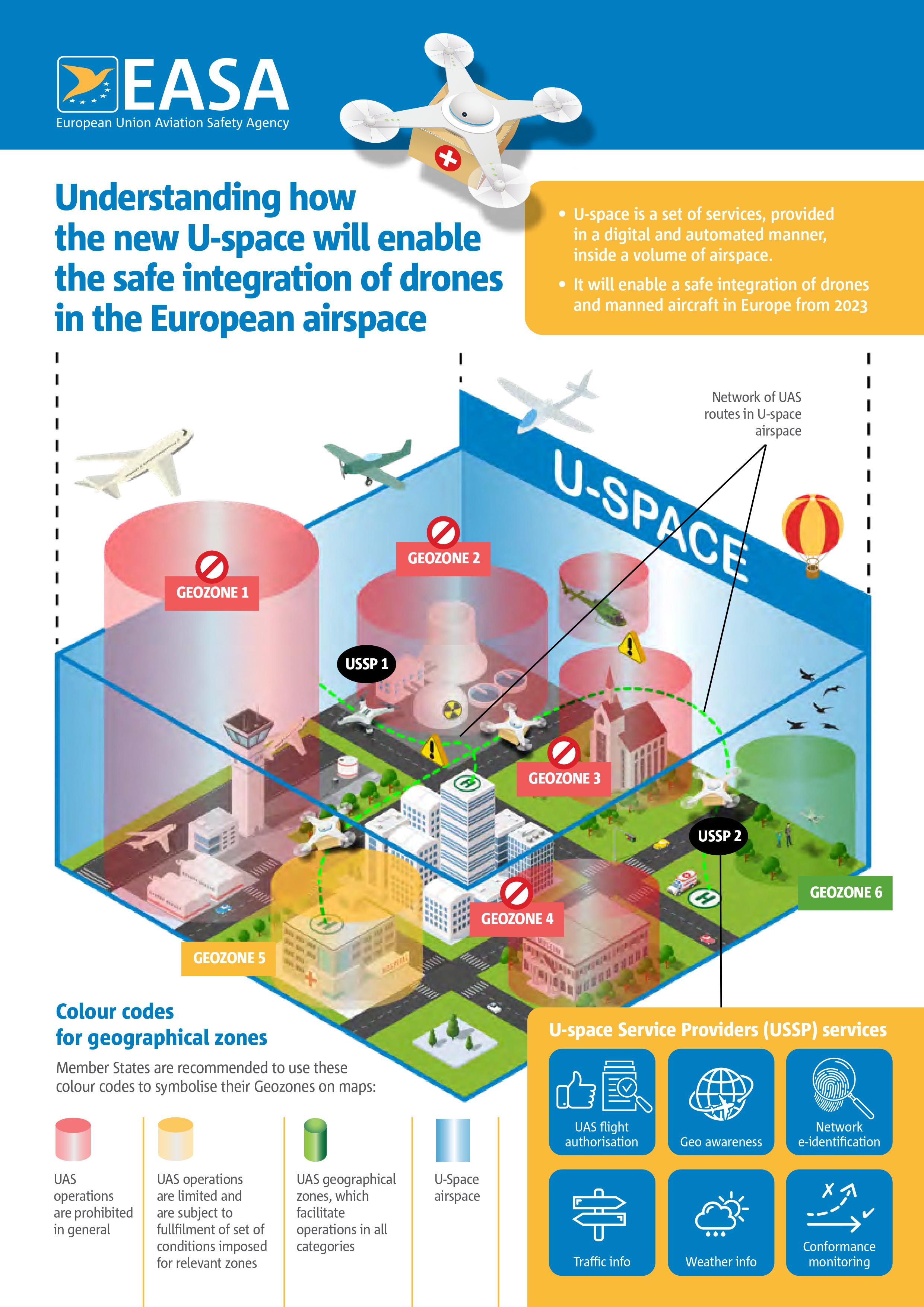

Example 1 - Safe airspace integration of UAS

"Developing an holistic approach to air traffic and airspace management, with the integration of UAS"

A step-by-step approach is necessary to integrate UAS safely into the existing airspace construct. This challenge may only be overcome through effective training, education and communication, where all stakeholders must understand each other's needs.

In certain circumstances (i.e. in the vicinity of airports), the establishment of geo-zoning can be a risk mitigation tool to prevent unlawful or inadvertent incursion by drones, in turn, reducing risk for all airspace users. Geo-zoning, however, is neither without its associated risks, nor is it infallible; training, education and regulation also have their parts to play.

In terms of regulation, UAS operations are a high priority and the impact of a drone collision on an aircraft depends on the category (Open, Specific or Certified). Open category drones (smaller ones) are the drones that cause the most incidents. There are a number of safety campaigns on the EASA community site around drone usage, especially around holiday’s and on the run up to Christmas when drones are often given as gifts and there are many new users who are unaware of the risks and unintended consequences.

The (peopled) flying community must have confidence in UAS operators. Training and education on safe operation of UASs is essential to the safety of all airspace users.

Societal and commercial drivers for UAS and UAV technology and capability continue to grow, and with them the risk of collision with manned aircraft. Not only the size of the UAS, but the intent/experience of the operator will also determine the level of risk. At the same time, we can not hinder the growth of said technology. Instead, we need to communicate to each other and member states on the risks and learnings, respect the rules and develop safe operations.

Example 2 - The management of repetitive defects

"Technical reliability and safety through the understanding and analyses of repetitive defects"

The management of repetitive defects touches all elements of aviation safety; from pilots, engineers, OEM’s and operators.

Many resources (including training) are necessary for the understanding and management of repetitive defects. The topic itself is not discussed enough and not well known, hence achieving a balance between capturing important defects and crying wolf needs to be considered. Therefore, the management of repetitive defects must be handled in a robust and holistic manner to increase safety performance.

As professionals, we must be able to communicate openly and across all disciplines to ensure that safety and the management of repetitive defects go hand in hand. OEMs cannot manage repetitive defects on their own; we all have an active role to play in the reporting cycle. Waiting for a report on reliability programs on a monthly basis is too late.

A lack of control of repetitive defects can cause hazards. A continuous approach to monitoring, analysis, investigation and feedback is key to actively controlling safety risks. This starts with a “mindset” on safety and open communication on reliability programmes between all stakeholders.