Improving survivability of rotorcraft occupants in the event of crash is a key safety priority in the EASA Rotorcraft Roadmap. The goal is to increase the number of rotorcraft fitted with Crash-Resistant Fuel Systems (CRFSs) and Crash-Resistant Seats and Structure (CRSSs). This article focuses on CRFS, provides some of the background on the topic and presents where things stand today.

EASA and OEMs recommend installing CRFS retrofit kits or other protective modifications and OEMs offer commercial incentives. Depending on the type of helicopter you operate and its age, the decision to fit CRFS rests with your organisation. It’s a tough decision that requires a difficult balance between cost, safety, and operational effectiveness. Therefore, we think it is useful to open the discussion and make these types of discussion easier at industry or organisational level.

Illustrating the safety vs. cost challenge

On 4th of April 2016, a Bell 206L N16760 suffered an engine power loss and crashed near Pigeon Forge, TN, USA. The helicopter was operated as a Part 91 local air tour flight.

According to the US National Transportation Safety Board (NTSB) accident report, the helicopter initially impacted trees near the top of a ridge, at an elevation of about 1 100 ft MSL, coming to rest in a wooded area near the bottom of the ridge.

Based on the injuries in the autopsy reports, The NTSB assessed the accident was likely to have been survivable for the pilot and one passenger had they received immediate emergency treatment and not been subject to a post-crash fire.

The aircraft was not fitted with a CRFS. In March 1994, Bell Helicopter released Service Instruction No. BHT-206-SI-2043 to improve the crash resistance of the original fuel system for 206L and 206L-1 helicopters, via incorporation of a retrofit kit. The retrofit kit has been available since 1994, but Bell Helicopters did not have a record of selling one of these retrofit kits at the time of this accident.

A review of the helicopter’s maintenance history revealed no record of modifications to the original fuel system to improve its crash resistance. Refer to the Torched Tennessee Tour Trip (B206L N16760) article posted by Aerossurance.

When disastrous events happen, improved crashworthiness reduces the severity of risk and can protect crew and passengers against more severe or even lethal consequences.

Solutions exist but the cost versus safety debate is a difficult one, hopefully some of the history of CRFS will help to balance the debate!

Where things stand now?

The requirements for Crash Resistant Fuel Systems (CRFS) were introduced in 1994 but is applicable only to new rotorcraft designs certified after this date or for fuel tank modifications designed after 1994. This requirement is applicable to EU and non-EU manufactured helicopters.

This means that any new rotorcraft design since 1994 is required to comply with the latest CRFS requirements contained in the Rotorcraft Certification Specifications CS-27 and CS-29.

Further analysis and assessment was carried out through EASA participation in the FAA Aviation Rulemaking Advisory Committee’s (ARAC) Rotorcraft Occupant Protection Working Group (ROPWG) set up in 2015. This Working Group assessed the cost and operational impact of mandating CRFS for newly produced rotorcraft and the existing rotorcraft fleet and balanced this against the safety benefit in terms of preventable fatalities. The outcome of this assessment was that “FAA should require in all rotorcraft, the installation (retrofit) of crash resistant fuel bladders that meet the requirements of the 50-foot fuel cell drop test in or out of structure, and that demonstrate a minimum of 250 lb puncture resistance”, with some potential exceptions to this rule.

This is what the US Congress has mandated the FAA to implement (and was not the result of a FAA Rulemaking activity). It must be noted that this is not a full compliance with the latest requirements and that the recommendation was for helicopters still in production.

EASA continued working at EU level to identify suitable solutions for the implementation of CRFS using an analytical approach called the Regulatory Impact Assessment (RIA) and Cost Benefit Analysis (CBA) that balances the safety benefits with the costs to the industry, which in some cases could make some parts of the industry financially unviable.

In parallel, EASA’s effort continued with extensive work to encourage CRFS embodiment, by approving Supplemental Type Certificates (STCS) for current fleet embodiment and working with the helicopter manufacturers to develop CRFS modifications. The result is that since October 2020 all EU helicopters currently in production (except one CS29 helicopter on which work is on-going to develop a fuel system crashworthiness) including the one certified pre-1994, have the CRFS in the baseline configuration.

This effort achieves even better crash resistance as it offers full compliant CRFS instead of partially complaint as mandated by the FAA. In addition, EASA has approved STCs and modifications that can be retrofitted so that operators have a retrofit option available on the market even for helicopter configurations not produced anymore.

EASA now goes a step further by working on the retrofit or partial retrofit of existing helicopter fleets when full retrofit is not technically possible. This is the purpose of Rulemaking Task (RMT).0710 ‘Improvement in the survivability of rotorcraft occupants in the event of an otherwise survivable crash’ in the European Plan for Aviation Safety (EPAS), the Terms of Reference (ToRs) for which were published in December 2021.

This means there are some helicopters are operating without CRFS installed.

Balancing risks and costs in the management system

Operating rules currently don’t mandate crash resistant fuel systems directly, but ORO.GEN.200 Management System has a requirement to identify risks and take mitigating action. You cannot ignore the risk of post-crash fire, but this doesn’t make the decision any easier.

As an accountable manager the challenge is to balance the need for installation against the cost of doing so.

What does risk management for a topic like this look like? What are your options?

- The EASA Rotorcraft Safety Roadmap encourages retrofitting CRFS kits in non-equipped aircraft. But perhaps CRFS is not available for the helicopter you operate, or the cost of installation could be unaffordable.

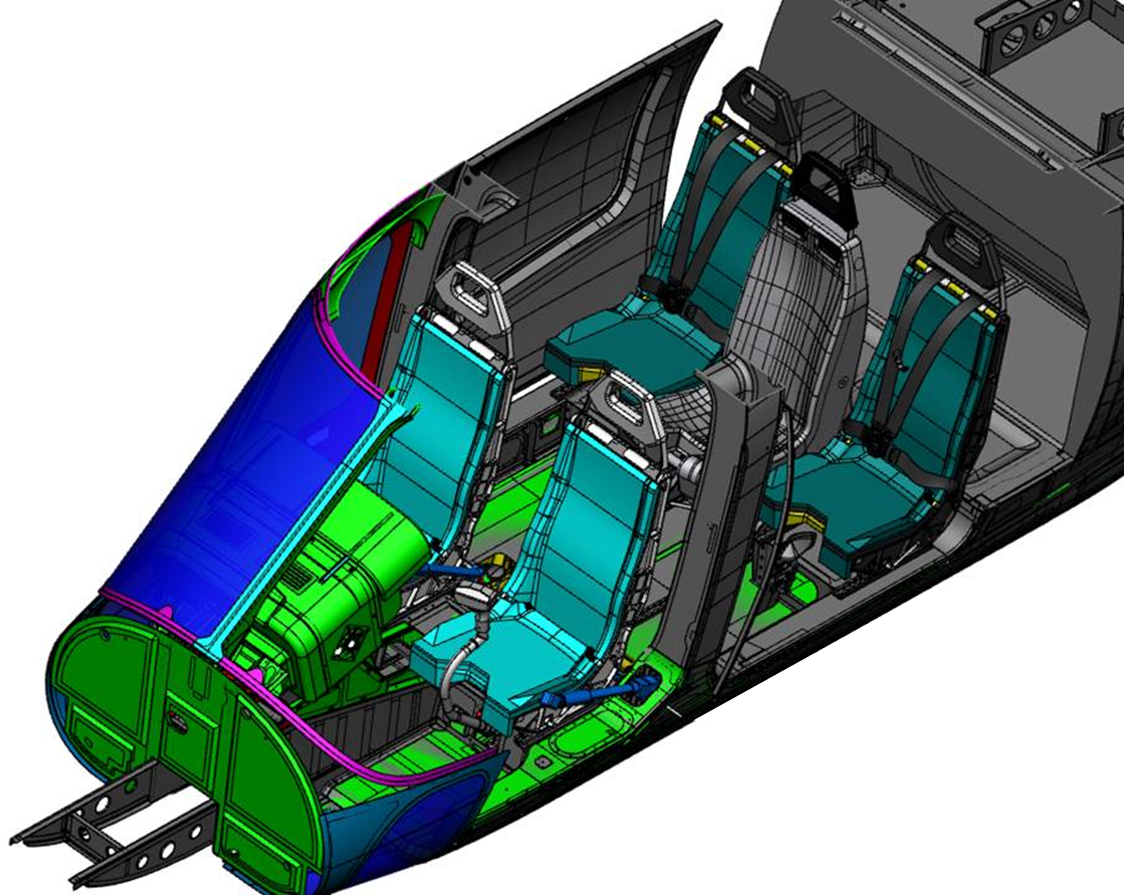

- The Roadmap also encourages, whenever possible, switching to modern helicopters. In an ideal world, when you buy or lease a helicopter for your operation, try to use helicopters with more recent designs that have CRFS, and other crashworthiness measures installed from delivery. Modern helicopters are also equipped with other technologies bringing additional safety and operational benefits. Of course that isn’t always possible. Especially if you have been operating the same helicopters for a long time and they are still serving you well.

- A third, less effective but less costly option, is using fire-resistant coveralls, gloves, helmets with protective visors and fire extinguishers. See Appendix 1.

A lot of this comes down to the type of operations you perform and where you perform them. If you are flying passengers or operating in locations where a post-crash fire could pose a risk to others on the ground, the risk is even higher.

In the appendices you will find more information about what it says about CRFS in the EASA Air Ops Rules (Appendix 1), the EASA Rotorcraft safety roadmap, CRFS and CRSS (Appendix 2), the actions taken in the US (Appendix 3), the ongoing changes to European airworthiness standards including retrospective application of recent design requirements (Appendix 4), and joint European efforts by the industry and authorities to improve post-crash fire protection (Appendix 5).

Conclusion

Ultimately, the decision is yours. It is worth considering that in some cases if you can upgrade your helicopters with CRFS but don’t do it, they may become obsolete, and you will take or accept unnecessary risks. You may also be called upon to defend your inaction in a court of law should one of your aircraft be involved in a fire and people perish. The more we can discuss the challenges at industry level, the easier these tough conversations will be.

Appendix 1 - Are CRFS and CRSS required by the Air OPS Regulation?

CRFS and CRSS aren’t required by Regulation (EU) No 965/2012.

The only expected change is for HEMS in line with RMT.0325 Helicopter emergency medical services’ performance and public interest sites. The HEMS Opinion is expected in early 2023 and Commission Implementing Rules and Decision in 2024 according to the European Plan for Aviation Safety.

In the rare cases where HEMS will be possible with single-engine helicopter, CRFS will be required.

ORO.GEN.200 Management system

ORO.GEN.200 doesn’t require CRFS and CRSS but requires an operator to establish, implement and maintain a management system that includes:

(1) clearly defined lines of responsibility and accountability, including a direct safety accountability of the accountable manager;

(2) a description of the overall philosophies and principles of the operator regarding safety, referred to as the safety policy; and

(3) the identification of aviation safety hazards entailed by the activities of the operator, their evaluation, and the management of associated risks, including taking actions to mitigate the risk and verify their effectiveness.

What does it mean in practice?

(1) As accountable manager you have the authority to decide if your aircraft are CRFS and CRSS-equipped. Particularly, if you operate aircraft certified before the 1980s and 1990s, whether to retrofit CRFS kits. A better option would be to consider operating more modern helicopters equipped with CRFS and other technology which brings additional safety and operational benefits. It’s not ideal but certain aircrew equipment and clothing, for instance fire-resistant coveralls, gloves, helmets (with protective visors) and fire extinguishers offer a certain degree of additional protection. They are possible mitigations in non CRFS-equipped aircraft that could be practical, particularly in flight-training and non-passenger operations.

(2) What safety aspirations, objectives and approach have you pledged to in the safety policy?

AMC1 ORO.GEN.200(s)(2) states that safety policy should include a commitment to improve towards the highest safety standards, to comply with all applicable legislation, meet all applicable standards and consider best practices. Senior management should provide necessary human and financial resources to implement the policy.

(3) The risk management process established as part of the management system should ensure analysis (in terms of likelihood and severity of occurrence), assessment (in terms of tolerability) and control (in terms of mitigation) of risks to an acceptable level. Considering the low probability, the risk of post-crash fire could be assessed technically acceptable despite the severe consequences. But can the risk of dying by fire be nonetheless tolerated? Another important aspect to consider is cost and financial risk. How much of available budget are you willing to allocate to prevent post-crash fire? You might conclude that investing on CRFS isn’t economically justified. However, in a court of law in a liability claim is likely to ask searching questions of the management’s decision to not install CRFS.

Appendix 2 - EASA Rotorcraft Safety Roadmap, CRFS and CRSS

Three Roadmap’s sections are particularly relevant regarding CRFSs and CRSSs:

III.1 Creating market incentives to push for safety and environment improvement

The idea is to find ways to 'incentivise’ safety by using market forces to facilitate fleet renewal. Mechanisms to create incentives are used in other industries such as the automotive and mobile phone industries.

Conversely, operational limitations for rotorcraft that do not implement certain safety improvements could be investigated. For example, a rotorcraft of an old design without crashworthy fuel tanks could still be allowed to operate. However, that type would not be authorised to commercially transport passengers.

Part-21 Changed Product Rule does not mandate introducing new technologies into older designs. The use of operational limitations could compensate for this in a proportionate manner. A close integration between Ops and Airworthiness is a central element in the Roadmap’s strategy.

III.8 Design and maintenance

The first objective is to reduce the number of rotorcraft flying in Europe without crashworthy fuel tanks and seats.

Regulatory actions aligned with ARAC recommendations have been initiated to increase the number of flying rotorcraft fitted with crashworthy fuel tanks and crashworthy seats. In parallel with the regulatory actions, authorities and manufacturers encourage operators to equip helicopters with retrofit kits or to operate recent CRFS and CRSS-equipped helicopters.

For new products, the grandfathering of rules needs to be carefully considered. For manufacturers, the current changed-product rules enable rotorcraft that are derivatives from older models to maintain the use of the original type certification basis. An FAA study showed that for a crashworthy fuel tanks requirement introduced in 1994, only a minority of the rotorcraft flying in the US are currently compliant. The situation isn’t any better in Europe. Commercial incentives and safety promotion are key.

III.9 Net safety benefit

A system or piece of equipment must comply with all the relevant certification requirements before it can be installed. In older helicopters, new equipment could provide additional safety benefits compared with the previous equipment. This positive contribution is not currently considered in certification policies, which makes the installation of new equipment more difficult. Operational safety benefits of these new features are so large that their availability is a compelling argument for putting them into service, as has already been seen in the automotive sector. As certification and introduction of these safety features have cost impacts for the stakeholders, a cost-benefit analysis should form the basis of any initiative.

The Roadmap suggests developing a rotorcraft safety-rating scheme aimed to enable operator and customer informed decision making.

A comprehensive comparative review of the schemes available in other industries, like EURO NCAP for automobiles. The review enabled to identify common elements to all these safety rating schemes. EASA progressed the concept definition and engage with manufacturers. The technologies including CFRSs and CRSSs are likely to be granting safety benefits.

Initiated in parallel in Europe and in the US, work on the rotorcraft safety scheme is since 2021 jointly performed within a dedicated Vertical Aviation Safety Team (VAST) Working Group.

Appendix 3 - US regulations on CRFS

FAA Aviation Rulemaking Advisory Committee (ARAC) Rotorcraft Occupant Protection Working Group (ROPWG)

In November 2015, a new task was assigned by the FAA for the ARAC to provide recommendations regarding occupant protection rulemaking in normal and transport category rotorcraft for older specification basis type designs. EASA participated in the ARAC’s ROPWG. Conclusions and recommendations are considered in RMT.0710 (see below) for application to existing rotorcraft types and European rotorcraft fleets.

US Congress H.R.3150 - Helicopter Fuel System Safety Act

The H.R.3150 - 115th Congress (2017-2018): Helicopter Fuel System Safety Act | Congress.gov | Library of Congress was introduced into the House on June 29, 2017. This bill prohibits a person from operating a newly manufactured helicopter in US airspace unless the FAA certifies that the helicopter's design complies with certain CRFS requirements. All helicopters manufactured after April 5th, 2020 and operated in the USA are required to have crash-resistant fuel tank.

Appendix 4 - Ongoing changes to European airworthiness standards including retrospective application of recent design requirements

RMT.0710 Improvement in the survivability of rotorcraft occupants in the event of crash

RMT.0710 objective is to improve rotorcraft occupant protection in the event of a survivable crash by increasing the number of rotorcraft fitted with CRFSs and CRSSs.

The safety and likelihood of survival of occupants in the event of a crash would significantly improve through the retroactive application of the current improvements in fuel tank crash resistance and occupant safety for rotorcraft.

Safety Recommendations

Safety recommendations have been put forward by accident investigation boards on the lack of CRFSs and CRSSs for rotorcraft certified before these dates.

Examples of safety recommendations addressed to EASA regarding CRFSs:

— Accident Robinson R44 VH-HWQ 21 March 2013 Australia (ASTL-2015-029) ATSB AO-2013-055-SR-029: “The ATSB recommends that the European [Union] Aviation Safety Agency take action to increase the number of existing rotorcraft that are fitted with a crash-resistant fuel system or have an equivalent level of safety in respect of post-impact fire.”

— Following an accident involving a AS350 (CS-HFT) in Portugal on 5 September 2019, the Portuguese accident investigation authority made the following recommendation to EASA (PORT-2020-001): “It is recommended that EASA follow its Rotorcraft Safety Roadmap publication principles, producing rulemaking documentation requiring retroactive application of the current improvements in fuel tank crash resistance for rotorcraft certified before the new certification specification for type design entered into force. Helicopters used for Commercial Operations shall be subject to this additional airworthiness requirement for operations.”

Example of safety recommendations addressed to EASA regarding CRSSs:

— Accident to Bell 204B (OE-XBT) on 23/07/2010 at Hinterthal, Austria AUST-2011-011 (unofficial translation): “To FAA, EASA: To meet the increased potential risk of aerial-work type of flights (external load flights), helicopters should be fitted with impact resistant pilot seats corresponding at least to the applicable certification requirements CS 27 (FAR 27) and CS 29 (FAR 29). In relation to this the granting of Grandfather Rights (CAR 7) should be reconsidered, and in a suitable and technically feasible extent evaluated, and improvements of the impact safety and the restraint system should be made.”

RMT.0710 addresses both CRFSs and CRSSs

RMT.0710 has two subtasks: Subtask 1 on CRFSs and Subtask 2 on CRSSs.

Taking into consideration the conclusions and recommendations from the ARAC ROPWG reports, this activity will:

— Determine the scale of the safety issues in terms of number of accidents and associated fatalities relating to a lack of CRFSs and CRSSs in existing European rotorcraft fleets.

— Create a European rotorcraft fleet model to identify the most effective means to enhance safety, making assumptions where necessary about future European rotorcraft fleets.

— Assess whether it is justifiable to apply CRFS and CRSS requirements retroactively and proportionately to existing small CS-27 rotorcraft, small CS-27 Category A rotorcraft and large CS-29 rotorcraft of European fleets and/or to the future production of already type-certified rotorcraft.

— Consider whether full compliance with the latest certification specifications for CRFSs and CRSSs is appropriate or whether partial compliance would be more proportionate and practicable.

Deliverables

Subtask 1 and Subtask 2 are expected to deliver:

— A Regulatory Impact Assessment (RIA) to assess the safety benefits of implementing CRFS, respectively CRSS, in new aircraft with an old type certificate and/or to retrofit existing fleet. The RIA will consider the economic, environmental, proportionality, and social impacts of such measures.

— If the above-mentioned RIA concludes that the safety benefits of implementing retroactive measures for CRFSs, respectively CRSSs, outweigh the potential economic, environmental, proportionality, and social impacts, propose amendments to Annex I (Part-26) to Regulation (EU) 2015/640 and to CS-26.

Refer to the Terms of Reference of RMT.0710 | EASA (europa.eu).

Appendix 5 - Joint European efforts by the industry and authorities to improve post-crash fire protection

CRFS

Joint efforts are undertaken by the industry and authorities to improve post-crash fire protection in the rotorcraft fleet. CRFS modifications have been developed and approved for instance for AS350 / EC130 and for AW119[1] helicopters:

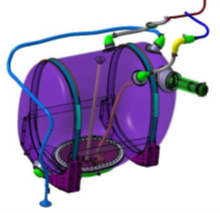

AW119 CFS Upper and Lower Tanks

Some authorities have even issued airworthiness directives to make a retrofit of CRFS mandatory.

EASA recommends to operators to modify the affected helicopters by incorporating the applicable modifications identified in SIB 2017-18R2 of 14 Jan. 2021 Installation of Crash Resistant Fuel System.

Turbine Engine Blade Shedding following Overspeed

Various threats or conditions can combine or trigger each other in an accident. A typical chain of events could be main rotor tip strike leading to transmission system failure and loss of loading on the engine output shaft resulting in engine overspeed. If flammable fluids or materials are released or exposed to a sufficient thermal source, a potential risk of post impact fire may exist. Sometimes, during blade shedding, extra thermal energy is released by the engine. Along with other thermal sources existing in a helicopter, this extra thermal energy is a potential ignition source. Ignition source has not always been clearly determined in post-impact fire occurrences.

Manufactures have reacted. For instance, Airbus Helicopters and SAFRAN have joined efforts to study some ways to reduce blade shedding occurrences in rotorcraft equipped with ARRIEL 2D engines and hence reduce post-impact fire potential. This has resulted in designing an electronic over-speed protection that, if still operational after the impact, reduces the risk of Power Turbine (PT) blade shedding through early over-speed detection and subsequent rapid fuel flow shut off.

This new function was introduced through a Full Authority Digital Engine Control (FADEC) software modification and wiring modification.

In SIB 2019-10, EASA recommends to operators to implement these modifications.

Fuel Leaks

Since November 1994, rotorcraft airworthiness standards addressing fuel system design include features intended to minimise fuel leaks and potential fuel ignition sources. That includes the majority of AH AS 350 / EC 130 fleet. The only exception is the EC 130 T2 that complies with these airworthiness standards since the original type certificate. Post TC modifications have been developed to bring the legacy fleet to the same level of safety for CRFS. Refer to EASA SIB 2017-18R2 for details. The entire fleet of AW119 is already compliant to 27.863 requirement.

The recommendation to improve post-crash fire protection similarly applies to other manufacturers.

Crash Resistant Seats

Efforts have been taken by the industry and authorities to improve protection of occupants in emergency crash landing conditions. Crash resistant seats solutions for flight crew and selected passenger configurations have been developed, for instance for AW119MKII helicopters, and are available for newly manufactured helicopters.

Industry recommends installing CRFS retrofit kits or other protective modifications and offers commercial incentives

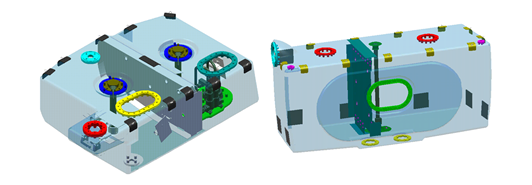

Manufacturers and STC providers (see picture of the Standard Aero solution below) strongly encourage operators to install CRFS.

Airbus Helicopters recommends operators to instal a CRFS retrofit kit, and in general any other equipment enabling the enhancement of fleet safety and reliability. Updated configurations and extended applicability of CRFS have been published in Airbus Helicopters SIN No. 3281-S-28. As a gesture of commitment to improving safety, Airbus Helicopters offers the CRFS retrofit kit at specific commercial conditions.

Other manufacturers also provide CRFS retrofit kits and use promotional actions to convince operators.

Acronyms

ARAC ROPWG FAA Aviation Rulemaking Advisory Committee

Rotorcraft Occupant Protection Working Group

CRFS Crash-Resistant Fuel System

CRSS Crash-Resistant Seats and Structure

FADEC Full Authority Digital Engine Control

(Airbus terminology)

HEMS Helicopter Emergency Medical Service

MSL Mean Sea level

NTSB US National Transportation Safety Board

PT Power Turbine

RIA Regulatory Impact Assessment

RMT Rule Making Task

SMS Safety Management System

VAST Vertical Aviation Safety Team

References

- NTSB accident investigation and Aerossurance article on the Torched Tennessee Tour Trip B206L N16760 accident of 4 April 2016.

- Bell Helicopter Service Instruction No. BHT-206-SI-2043.

- Aerossurance Torched Tennessee Tour Trip (B206L N16760) article.

- Regulation (EU) No 965/2012 Air Operations, Annex III (Part ORO), SUBPART GEN GENERAL REQUIREMENTS, SECTION 2 Management, ORO.GEN.200 Management systems.

- Rotorcraft Occupant Protection Working Group (ROPWG) Task 5 Crash Resistant Fuel Systems (CRFS) Final analysis report to the Aviation Rulemaking Advisory Committee (ARAC) Submitted on 15 March 2018.

- Rotorcraft Occupant Protection Working Group (ROPWG) Task 6 Final analysis report to the Aviation Rulemaking Advisory Committee (ARAC), revised on 27 September 2018.

- Rotorcraft Occupant Protection Working Group (ROPWG) Task 5 Crash Resistant Seats and Structure (CRSS) Final analysis report to the Aviation Rulemaking Advisory Committee (ARAC), submitted on 29 January 2018.

- US Congress H.R.3150 - 115th Congress (2017-2018): Helicopter Fuel System Safety Act.

- EASA Rotorcraft Safety Roadmap, Dec. 2018.

- European Plan for Aviation Safety (EPAS) 2022-2026, Volume II, RMT.0710 Improvement in the survivability of rotorcraft occupants in the event of crash, and 80 RMT.0325 Helicopter emergency medical services’ performance and public interest sites.

- Terms of Reference of RMT.0710 and RMT.0325 (OPS.057(a)).

- EASA SIB 2017-18R2 Installation of Crash Resistant Fuel System.

- EASA SIB 2019-10 Power Turbine Over-Speed Protection on ARRIEL 2D Engines.

- Airbus Helicopters SIN No. 3281-S-28, Revision 2, Dec. 2020.

[1] AW119 CRFS compliant to the US regulation, certified through FAA STC and validated by EASA

Please log in or sign up to comment.