AMC 20-8A Occurrence reporting

ED Decision 2020/010/R

1. INTENT

This AMC is interpretative material and provides guidance in order to determine when occurrences should be reported to EASA, competent authorities and other organisations.

It also describes the objective of the overall occurrence-reporting system, including internal and external functions.

2. APPLICABILITY

(a) This AMC only applies to occurrence reporting by persons or organisations that are subject to Regulation (EU) No 748/2012 and Regulation (EU) No 1321/2014.

(b) In most cases, the obligation to report is on the holders of a certificate or approval, which in most cases are organisations, but in some cases can be a natural person. In addition some reporting requirements are directed to persons. However, in order not to complicate the text, only the term ‘organisation’ is used.

(c) The AMC does not specifically address dangerous goods reporting. This subject is covered in specific operational requirements and guidance, and in European Union regulations and ICAO documents, namely:

(i) Commission Regulation (EU) No 965/2012 of 5 October 2012 laying down technical requirements and administrative procedures related to air operations pursuant to Regulation (EC) No 216/2008 of the European Parliament and of the Council;

(ii) ICAO Annex 18 ‘Safe Transport of Dangerous Goods by Air’; and

(iii) ICAO Doc 9284-AN/905, ‘Technical Instructions for the Safe Transport of Dangerous Goods by Air’.

3. OBJECTIVE OF OCCURRENCE REPORTING

(a) The occurrence-reporting system is an essential part of the overall monitoring function. The objective of the occurrence-reporting, collection, investigation and analysis systems described in the applicable requirements of Regulation (EU) 2018/1139, as well as of Regulation (EU) No 376/2014 and the delegated and implementing acts adopted on the basis thereof is to use the reported information to contribute to the improvement of aviation safety and it should not be used to attribute blame or liability or to establish benchmarks for safety performance.

(b) The detailed objectives of the occurrence-reporting systems are to:

(i) enable an assessment of the safety implications of each occurrence to be made, including previous similar occurrences, so that any necessary action can be initiated; this includes determining what had occurred and why, and what might prevent a similar occurrence from happening in the future;

(ii) ensure that knowledge of occurrences is disseminated so that other persons and organisations may learn from them.

(c) The occurrence-reporting system is complementary to the normal day-to-day procedures and ‘control’ systems and is not intended to duplicate or supersede any of them. The occurrence-reporting system is a tool to identify those occasions where routine procedures have failed.

(d) Occurrences should remain in the database when judged reportable by the person submitting the report as the significance of such reports may only become obvious at a later date.

4. REPORTING TO EASA AND COMPETENT AUTHORITIES

(a) For organisations that have their principal place of business in a Member State, Commission Implementing Regulation (EU) 2015/1018 provides a classification of the occurrences in civil aviation for which reporting is mandatory. This list should not be understood as being an exhaustive collection of all the issues that may pose a significant risk to aviation safety, and therefore reporting should not be limited to the items listed therein and the additional items identified in points 21.A.129(f) and 21.A.165(f) of Part 21.

For organisations that do not have their principal place of business in a Member State, such a list is provided in Section 9.

(b) These lists are based on the following general airworthiness requirements:

(i) The design rules for products, parts and appliances prescribe that an occurrence that is defined as a failure, malfunction, defect or other occurrence related to a product or part, which has resulted or may result in an unsafe condition, must be reported to EASA.

(ii) The product and part production rules prescribe that products or parts released from the production organisation with deviations from the applicable design data that could lead to a potential unsafe condition, as identified with the holder of the type certificate (TC) or design approval holder (DAH), must be reported to the competent authority.

(iii) The continuing airworthiness rules stipulate that an occurrence that is defined as any safety-related event or condition of an aircraft or component identified by the organisation that endangers or, if not corrected or addressed, could endanger an aircraft, its occupants or any other person, must be reported to the competent authority.

(iv) In addition, the continuing airworthiness rules prescribe that any incident, malfunction, technical defect, exceedance of technical limitations, occurrence that would highlight inaccurate, incomplete or ambiguous information, contained in the Instructions for Continued Airworthiness (ICA) established in accordance with Regulation (EU) No 748/2012, or other irregular circumstance that has or may have endangered an aircraft, its occupants or any other person, must be reported to the competent authority and to the organisation responsible for the design of the aircraft.

(c) Reporting does not remove the responsibility of the reporter or the organisation to initiate actions to prevent similar occurrences from happening in the future.

(d) A design or maintenance programme may include additional reporting requirements for failures or malfunctions associated with that approval or programme.

5. REPORTING TIME — MANDATORY REPORTING — INITIAL REPORT

(a) The period of 72 hours is normally understood to start from when the person or organisation became aware of the occurrence. This means that there may be up to 72 hours maximum for a person to report to the organisation or to directly report to the competent authority, plus 72 hours maximum for the organisation to report to the competent authority.

(b) Within the overall limit of 72 hours for the submission of a report, the organisation should determine the degree of urgency based on the severity of consequence judged to have resulted from the occurrence:

(i) Where an occurrence is judged to have resulted in an immediate and particularly severe consequence, EASA and/or the competent authority expects to be notified immediately, and by the fastest possible means (e.g. telephone, fax, telex, e-mail) of whatever details are available at that time. This initial notification should then be followed up by a report within 72 hours.

A typical example of severe consequences would be an uncontained Engine failure that results in damage to the aircraft primary structure.

(ii) Where the occurrence is judged to have resulted in a less immediate and less significant risk, the report submission may be delayed up to the maximum of 72 hours in order to provide more details or more reliable information.

6. CONTENT OF INITIAL REPORTS

(a) For organisations that have their principal place of business in a Member State, the content of mandatory reports and, where possible, voluntary reports, is defined in Annex I to Regulation (EU) No 376/2014.

(b) For organisations that do not have their principal place of business in a Member State, mandatory reports and, where possible, voluntary reports, should include the information below:

(i) when: UTC date;

(ii) where: State/area of occurrence — location of occurrence;

(iii) aircraft-related information: aircraft identification, State of Registry, make-model series, aircraft category, propulsion type, mass group, aircraft serial number, and aircraft registration number;

(iv) aircraft operation and history of flight: operator, type of operation, last departure point, planned destination, flight phase;

(v) weather: the relevant weather;

(vi) where relevant, air-navigation-services-(ANS)-related information: ATM contribution, service affected, ATS unit name;

(vii) where relevant, aerodrome-related information: location indicator (ICAO airport code), location on the aerodrome; and

(viii) aircraft-damage- or personal-injury-related information: severity in terms of the highest level of damage and injury, the number and type of injuries to persons on the ground and in the aircraft.

7. REPORTING TIME — FOLLOW-UP REPORTS

(a) For organisations that have their principal place of business in a Member State, the reporting timelines for follow-up reports are those defined in Article 13 of Regulation (EU) No 376/2014.

(b) For organisations that do not have their principal place of business in a Member State, the following applies: where the organisation identifies an actual or potential aviation safety risk as a result of their analysis of occurrences or groups of occurrences reported to EASA, it should:

(i) transmit the following information to EASA within 30 days from the date of notification of the occurrence to EASA:

(1) the preliminary results of the risk assessment performed; and

(2) any preliminary mitigation action to be taken;

(ii) where required, transmit the final results of the risk analysis to EASA as soon as they are available and, in principle, no later than 3 months from the date of the initial notification of the occurrence to EASA.

8. REPORTING AMONG ORGANISATIONS

(a) In addition to reporting occurrences to the competent authority or EASA, reporting among organisations should be considered. Such reporting will depend on the type of the organisation, its interfaces with other organisations, and their respective safety policies and procedures, as well as the extent of contracting or subcontracting.

(b) Organisations may develop a customised list of occurrences to be reported among them, adapted to their particular aircraft, operations or products, and the organisations with which they interface. Such a customised list of occurrences to be reported among organisations is usually included or referenced in the organisation’s expositions/handbooks/manuals. Any such lists should, however, not be considered to be definitive or exhaustive, and it is essential for the reporter to use their judgement of the degree of risk or potential hazard that is involved.

(c) The following provides a non-exhaustive list of reporting lines that exist for the reporting of occurrences among organisations related to unsafe or non-airworthy conditions:

(i) production organisation to the organisation responsible for the design;

(ii) maintenance organisation/continuing airworthiness management organisation (CAMO) to the organisation responsible for the design;

(iii) maintenance organisation/CAMO to the operator;

(iv) operator to the organisation responsible for the design; and

(v) production organisation to another production organisation.

(d) The ‘design approval holder’ is a general term, which can be any one or a combination of the following natural persons or organisations:

(i) the holder of type certificate (TC) of an aircraft, Engine or Propeller;

(ii) the holder of a supplemental type certificate (STC) on an aircraft, Engine or Propeller;

(iii) the holder of a European technical standard order (ETSO) authorisation; or

(iv) the holder of a repair design approval or a change to a type design approval.

(e) If it can be determined that the occurrence has an impact on or is related to an aircraft component which is covered by a separate design approval/authorisation (TC, STC or ETSO), then the holder of such approval/authorisation should be informed. Such information must be part of the reporting to the ‘main’ design approval holder. If an occurrence concerns a component which is covered by a TC, STC, repair or change design approval or an ETSO authorisation (e.g. during maintenance), then only that TC, STC, repair or change design approval holder or ETSO authorisation holder needs to be informed by the reporting person or organisation that first determined the impact of the TC, STC, repair or change design or ETSO authorisation.

(f) Any organisation that reports to the design approval holder should actively support any investigations that may be initiated by that organisation. Support should be provided by a timely response to information requests, and by making available the affected components, parts or appliances for the purpose of the investigation, subject to an agreement with the respective component, part or appliance owners. Design approval holders are expected to provide feedback to the reporting organisations on the results of their investigations.

(g) To ensure that there is effective reporting among organisations, it is important that:

(i) an interface is established between the organisations to ensure that there is an effective and timely exchange of information related to occurrences;

(ii) any relevant safety issue is identified; and

(iii) it is clearly established which party is responsible for taking further action, if required.

(h) Organisations should establish procedures to be used for reporting among them, which should include as a minimum:

(i) a description of the applicable requirements for reporting;

(ii) the scope of such reporting, considering the organisation’s interfaces with other organisations, including any contracting and subcontracting;

(iii) a description of the reporting mechanism, including reporting forms, means, and deadlines;

(iv) safeguards to ensure the confidentiality of the reporter and protection of personal data; and

(v) the responsibilities of the organisations and personnel involved in reporting, including for reporting to the competent authority.

Such procedures should be included in the organisation’s expositions/handbooks/manuals.

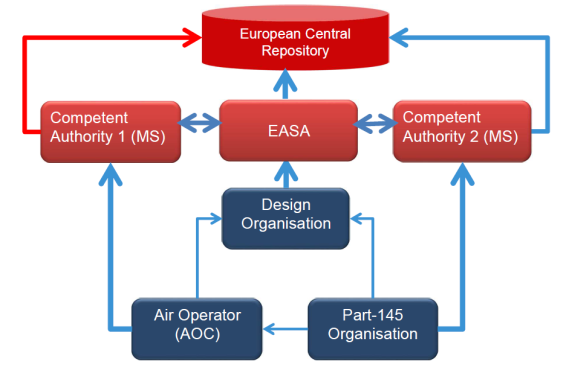

Figure 1 below presents a simplified scheme of the reporting lines.

Figure 1

Figure 1

9. REPORTABLE OCCURRENCES — MANDATORY REPORTING

For organisations that do not have their principal place of business in a Member State, the text below provides a classification of occurrences in civil aviation for which reporting is mandatory. This list should not be understood as being an exhaustive collection of all the issues that may pose a significant risk to aviation safety and, therefore, reporting should not be limited to the items listed therein and the additional items identified in points 21.A.129(f) and 21.A.165(f) of Part 21.

9.1. MANUFACTURING

Products, parts or appliances released from the production organisation with deviations from the applicable design data that could lead to a potential unsafe condition as identified by the holder of the type certificate or design approval.

9.2. DESIGN

Any failure, malfunction, defect or other occurrence related to a product, part or appliance which has resulted, or may result, in an unsafe condition.

Remark: This list is applicable to occurrences that occur on a product, part or appliance covered by the type certificate (TC), restricted type certificate (RTC), supplemental type certificate (STC), ETSO authorisation, major repair design approval or any other relevant approval deemed to have been issued in line with Commission Regulation (EU) No 748/2012.

9.3. MAINTENANCE AND CONTINUING AIRWORTHINESS MANAGEMENT

(a) Serious structural damage (for example, cracks, permanent deformation, delamination, debonding, burning, excessive wear, or corrosion) found during maintenance of the aircraft or component.

(b) Serious leakage or contamination of fluids (for example, hydraulic, fuel, oil, gas or other fluids).

(c) A failure or malfunction of any part of an Engine or power plant and/or transmission that results in either or both of the following:

(i) non-containment of components/debris;

(ii) failure of the Engine mount structure.

(d) Damage to a Propeller, or a failure or defect of a Propeller, which could lead to in-flight separation of the Propeller or any major portion of the Propeller and/or malfunctions of the Propeller control.

(e) Damage to a main rotor gearbox/attachment, or a failure or defect of a main rotor gearbox/attachment, which could lead to an in-flight separation of the rotor assembly and/or malfunctions of the rotor control.

(f) A significant malfunction of a safety-critical system or equipment, including a malfunction of an emergency system or equipment during maintenance testing, or a failure to activate these systems after maintenance.

(g) The incorrect assembly or installation of components of the aircraft found during an inspection or test procedure that was not intended for that specific purpose.

(h) An incorrect assessment of a serious defect, or a serious non-compliance with the MEL or the technical logbook procedures.

(i) Serious damage to the electrical wiring interconnection system (EWIS).

(j) Any defect in a life-controlled critical part that causes its retirement before the completion of its full service life.

(k) The use of products, components or materials from an unknown or suspect origin, or unserviceable critical components.

(l) Misleading, incorrect or insufficient applicable maintenance data or procedures, including language issues, which could lead to significant maintenance errors.

(m) The incorrect control or application of aircraft maintenance limitations or scheduled maintenance.

(n) Releasing an aircraft to service from maintenance if there remains any non-compliance which endangers flight safety.

(o) Serious damage caused to an aircraft during maintenance activities due to incorrect maintenance or the use of inappropriate or unserviceable ground support equipment that requires additional maintenance actions.

(p) Identified occurrences of burning, melting, smoke, arcing, overheating or fire.

(q) Any occurrence in which human performance, including the fatigue of the personnel, has directly contributed, or could have contributed, to an accident or a serious incident.

(r) A significant malfunction, reliability issue, or recurrent recording quality issue that affects a flight recorder system (such as a flight data recorder system, a data link recording system or a cockpit voice recorder system) or a lack of the information needed to ensure the serviceability of a flight recorder system.

[Amdt 20/19]