PART 1 — Requirements for a class C0 Unmanned aircraft system

Regulation (EU) 2020/1058

A class C0 UAS bears the following class identification label on the UA:

A class C0 UAS shall comply with the following:

(1) have an MTOM of less than 250 g, including payload;

(2) have a maximum speed in level flight of 19 m/s;

(3) have a maximum attainable height above the take-off point limited to 120 m;

(4) be safely controllable with regards to stability, manoeuvrability and the command and control link performance, by a remote pilot following the manufacturer’s instructions, as necessary under all anticipated operating conditions including following the failure of one or, if appropriate, more systems;

(5) be designed and constructed in such a way as to minimise injury to people during operation, sharp edges shall be avoided, unless technically unavoidable under good design and manufacturing practice. If equipped with propellers, the UA shall be designed in such a way as to limit any injury that may be inflicted by the propeller blades;

(6) be exclusively powered by electricity;

(7) if equipped with a follow-me mode and when this function is on, be in a range not exceeding 50 m from the remote pilot, and make it possible for the remote pilot to regain control of the UA;

(8) be placed on the market with manufacturer’s instructions providing:

(a) the characteristics of the UA including but not limited to the:

— class of the UA

— UA mass (with a description of the reference configuration) and the maximum take-off mass (MTOM);

— general characteristics of allowed payloads in terms of mass, dimensions, interfaces with the UA and other possible restrictions;

— equipment and software to control the UA remotely; and

— a description of the behaviour of the UA in case of a loss of the command and control link;

(b) clear operational instructions;

(c) operational limitations (including but not limited to meteorological conditions and day/night operations); and

(d) appropriate description of all the risks related to UAS operations adapted for the age of the user;

(9) include an information notice published by the European Union Aviation Safety Agency (EASA) providing the applicable limitations and obligations, in accordance with Implementing Regulation (EU) 2019/947;

(10) Points (4), (5) and (6) do not apply to UAS that are toys in the meaning of Directive 2009/48/EC on the safety of toys.

PART 2 — Requirements for a class C1 Unmanned aircraft system

Regulation (EU) 2020/1058

A class C1 UAS bears the following class identification label on the UA:

A class C1 UAS shall comply with the following:

(1) be made of materials and have performance and physical characteristics such as to ensure that in the event of an impact at terminal velocity with a human head, the energy transmitted to the human head is less than 80 J, or, as an alternative, shall have an MTOM of less than 900 g, including payload;

(2) have a maximum speed in level flight of 19 m/s;

(3) have a maximum attainable height above the take-off point limited to 120 m or be equipped with a system that limits the height above the surface or above the take-off point to 120 m or to a value selectable by the remote pilot; if the value is selectable, clear information about the height of the UA above the surface or take-off point during flight shall be provided to the remote pilot;

(4) be safely controllable with regards to stability, manoeuvrability and the command and control link performance, by a remote pilot with adequate competency as defined in Implementing Regulation (EU) 2019/947 and following the manufacturer’s instructions, as necessary under all anticipated operating conditions including following the failure of one or, if appropriate, more systems;

(5) have the requisite mechanical strength for the UA, including any necessary safety factor, and, where appropriate, stability to withstand any stress to which it is subjected to during use without any breakage or deformation that might interfere with its safe flight;

(6) be designed and constructed in such a way as to minimise injury to people during operation, sharp edges of the UA shall be avoided, unless technically unavoidable under good design and manufacturing practice; if equipped with propellers, the UA shall be designed in such a way as to limit any injury that may be inflicted by the propeller blades;

(7) in case of a loss of the command and control link, have a reliable and predictable method for the UA to recover the command and control link or if this fails, terminate the flight in a way that reduces the effect on third parties in the air or on the ground;

(8) unless it is a fixed-wing UA, have a guaranteed A-weighted sound power level LWA determined as per Part 13 not exceeding the levels established in Part 15;

(9) unless it is a fixed-wing UA, have the indication of the guaranteed A-weighted sound power level affixed on the UA and/or its packaging as per Part 14;

(10) be exclusively powered by electricity;

(11) have a unique serial number compliant with standard ANSI/CTA-2063-A-2019, Small Unmanned Aerial Systems Serial Numbers, 2019;

(12) have a direct remote identification that:

(a) allows the upload of the UAS operator registration number required in accordance with Article 14 of Implementing Regulation (EU) 2019/947 and any additional number provided by the registration system; the system shall perform a consistency check verifying the integrity of the full string provided to the UAS operator at the time of registration; in case of inconsistency, the UAS shall emit an error message to the UAS operator;

(b) ensures, in real time during the whole duration of the flight, the direct periodic broadcast from the UA using an open and documented transmission protocol, in a way that it can be received directly by existing mobile devices within the broadcasting range, of at least the following data:

(i) the UAS operator registration number and the verification code provided by the Member State of registration during the registration process unless the consistency check defined in point (a) is not passed;

(ii) the unique physical serial number of the UA compliant with point (11);

(iii) the time-stamp, the geographical position of the UA and its height above the surface or take-off point;

(iv) the route course measured clockwise from true north and ground speed of the UA;

(v) the geographical position of the remote pilot or, if not available, the take-off point; and

(vi) an indication of the emergency status of the UAS;

(c) reduces the ability of tampering the functionality of the direct remote identification system;

(13) be equipped with a geo-awareness function that provides:

(a) an interface to load and update data containing information on airspace limitations related to UA position and height imposed by the UAS geographical zones, as defined by Article 15 of Implementing Regulation (EU) 2019/947, which ensures that the process of loading or updating such data does not degrade its integrity and validity;

(b) a warning alert to the remote pilot when a potential breach of airspace limitations is detected; and

(c) information to the remote pilot on the UA’s status as well as a warning alert when its positioning or navigation systems cannot ensure the proper functioning of the geo‑awareness function;

(14) if the UA has a function that limits its access to certain airspace areas or volumes, this function shall operate in such a manner that it interacts smoothly with the flight control system of the UA without adversely affecting flight safety; in addition, clear information shall be provided to the remote pilot when this function prevents the UA from entering these airspace areas or volume;

(15) provide the remote pilot with clear warning when the battery of the UA or its command unit reaches a low level such that the remote pilot has sufficient time to safely land the UA;

(16) be equipped:

(a) with lights for the purpose of controllability of the UA; and

(b) with at least one green flashing light for the purpose of conspicuity of the UA at night to allow a person on the ground to distinguish the UA from a manned aircraft;

(17) if equipped with a follow-me mode and when this function is on, be in a range not exceeding 50 m from the remote pilot, and make it possible for the remote pilot to regain control of the UA;

(18) be placed on the market with manufacturer’s instructions providing:

(a) the characteristics of the UA including but not limited to the:

— class of the UA;

— UA mass (with a description of the reference configuration) and the maximum take-off mass (MTOM);

— general characteristics of allowed payloads in terms of mass, dimensions, interfaces with the UA and other possible restrictions;

— equipment and software to control the UA remotely;

— the procedures to upload the UAS operator registration number into the remote identification system;

— reference of the transmission protocol used for the direct remote identification system emission;

— sound power level; and

— a description of the behaviour of the UA in case of a loss of data link; and the method to recover the command and control link of the UA.

(b) clear operational instructions;

(c) procedure to upload the airspace limitations into the geo-awareness function;

(d) maintenance instructions;

(e) troubleshooting procedures;

(f) operational limitations (including but not limited to meteorological conditions and day/night operations); and

(g) appropriate description of all the risks related to UAS operations;

(19) include an information notice published by EASA providing the applicable limitations and obligations, in accordance with Implementing Regulation (EU) 2019/947;

(20) if equipped with a network remote identification system it shall:

(a) allow, in real time during the whole duration of the flight, the transmission from the UA using an open and documented transmission protocol, in a way that it can be received through a network, of at least the following data;

(i) the UAS operator registration number and the verification code provided by the Member State of registration during the registration process unless the consistency check defined in point (a) is not passed;

(ii) the unique serial number of the UA compliant with point (11);

(iii) the time stamp, the geographical position of the UA and its height above the surface or take-off point;

(iv) the route course measured clockwise from true north and ground speed of the UA;

(v) the geographical position of the remote pilot or, if not available, the take-off point; and

(vi) an indication of the emergency status of the UAS;

(b) reduce the ability of tampering the functionality of the direct remote identification system.

PART 3 — Requirements for a class C2 Unmanned aircraft system

Regulation (EU) 2020/1058

A class C2 UAS bears the following class identification label on the UA:

A class C2 UAS shall comply with the following:

(1) have an MTOM of less than 4 kg, including payload;

(2) have a maximum attainable height above the take-off point limited to 120 m or be equipped with a system that limits the height above the surface or above the take-off point to 120 m or to a value selectable by the remote pilot. If the value is selectable, clear information about the height of the UA above the surface or take-off point during flight shall be provided to the remote pilot;

(3) be safely controllable with regard to stability, manoeuvrability and the command and control link performance, by a remote pilot with adequate competency as defined in Implementing Regulation (EU) 2019/947 and following the manufacturer’s instructions, as necessary under all anticipated operating conditions including following the failure of one or, if appropriate, more systems;

(4) have the requisite mechanical strength for the UA, including any necessary safety factor, and, where appropriate, stability to withstand any stress to which it is subjected to during use without any breakage or deformation that might interfere with its safe flight;

(5) in the case of a tethered UA, have a tensile length of the tether that is less than 50 m and a mechanical strength that is no less than:

(a) for heavier-than-air aircraft, 10 times the weight of the aerodyne at maximum mass;

(b) for lighter-than-air aircraft, 4 times the force exerted by the combination of the maximum static thrust and the aerodynamic force of the maximum allowed wind speed in flight;

(6) be designed and constructed in such a way as to minimise injury to people during operation, sharp edges of the UA shall be avoided, unless technically unavoidable under good design and manufacturing practice; if equipped with propellers, the UA shall be designed in such a way as to limit any injury that may be inflicted by the propeller blades;

(7) unless tethered, in case of a loss of the command and control link, have a reliable and predictable method for the UA to recover the command and control link or, if it fails, terminate the flight in a way that reduces the effect on third parties in the air or on the ground;

(8) unless tethered, be equipped with a command and control link protected against unauthorised access to the command and control functions;

(9) unless it is a fixed-wing UA, be equipped with a low-speed mode selectable by the remote pilot and limiting the ground speed to no more than 3 m/s.

(10) unless it is a fixed-wing UA, have a guaranteed A-weighted sound power level LWA determined as per Part 13 not exceeding the levels established in Part 15;

(11) unless it is a fixed-wing UA, have the indication of the guaranteed A-weighted sound power level affixed on the UA and/or its packaging as per Part 14;

(12) be exclusively powered by electricity;

(13) have a unique serial number compliant with standard ANSI/CTA-2063-A-2019, Small Unmanned Aerial Systems Serial Numbers, 2019;

(14) have a direct remote identification that:

(a) allows the upload of the UAS operator registration number required in accordance with Article 14 of Implementing Regulation (EU) 2019/947 and any additional number provided by the registration system. The system shall perform a consistency check verifying the integrity of the full string provided to the UAS operator at the time of registration. In case of inconsistency, the UAS shall emit an error message to the UAS operator;

(b) ensures, in real time during the whole duration of the flight, the direct periodic broadcast from the UA using an open and documented transmission protocol, in a way that it can be received directly by existing mobile devices within the broadcasting range, of at least the following data:

(i) the UAS operator registration number and the verification code provided by the Member State during the registration process, unless the consistency check defined in point (a) is not passed;

(ii) the unique serial number of the UA compliant with point (13);

(iii) the time stamp, the geographical position of the UA and its height above the surface or take-off point;

(iv) the route course measured clockwise from true north and ground speed of the UA;

(v) the geographical position of the remote pilot or, if not available, the take-off point; and

(vi) an indication of the emergency status of the UAS;

(c) reduces the ability of tampering the functionality of the direct remote identification system.

(15) be equipped with a geo-awareness function that provides:

(a) an interface to load and update data containing information on airspace limitations related to UA position and height imposed by the UAS geographical zones, as defined by Article 15 of Implementing Regulation (EU) 2019/947, which ensures that the process of loading or updating of this data does not degrade its integrity and validity;

(b) a warning alert to the remote pilot when a potential breach of airspace limitations is detected; and

(c) information to the remote pilot on the UA’s status as well as a warning alert when its positioning or navigation systems cannot ensure the proper functioning of the geo‑awareness function;

(16) if the UA has a function that limits its access to certain airspace areas or volumes, this function shall operate in such a manner that it interacts smoothly with the flight control system of the UA without adversely affecting flight safety; in addition, clear information shall be provided to the remote pilot when this function prevents the UA from entering these airspace areas or volumes;

(17) provide the remote pilot with clear warning when the battery of the UA or its command unit reaches a low level such that the remote pilot has sufficient time to safely land the UA;

(18) be equipped:

(a) with lights for the purpose of controllability of the UA; and

(b) with at least one green flashing light for the purpose of conspicuity of the UA at night to allow a person on the ground, to distinguish the UA from a manned aircraft;

(19) be placed on the market with manufacturer’s instructions providing:

(a) the characteristics of the UA including but not limited to the:

— class of the UA;

— UA mass (with a description of the reference configuration) and the maximum take-off mass (MTOM);

— general characteristics of allowed payloads in terms of mass, dimensions, interfaces with the UA and other possible restrictions;

— equipment and software to control the UA remotely;

— the procedures to upload the UAS operator registration number into the remote identification system;

— reference of the transmission protocol used for the direct remote identification system emission;

— sound power level; and

— description of the behaviour of the UA in case of a loss of the command and control link, and the method to recover the command and control link of the UA; and

(b) clear operational instructions;

(c) the procedure to upload the airspace limitations into the geo-awareness function;

(d) maintenance instructions;

(e) troubleshooting procedures;

(f) operational limitations (including but not limited to meteorological conditions and day/night operations); and

(g) appropriate description of all the risks related to UAS operations;

(20) include an information notice published by EASA providing the applicable limitations and obligations, in accordance with Implementing Regulation (EU) 2019/947;

(21) if equipped with a network remote identification system it shall:

(a) ensure, in real time during the whole duration of the flight, the transmission from the UA using an open and documented transmission protocol, in a way that it can be received through a network, of at least the following data:

(i) the UAS operator registration number and the verification code provided by the Member State of registration during the registration process unless the consistency check defined in point 14(a) is not passed;

(ii) the unique serial number of the UA compliant with point (13);

(iii) the time stamp, the geographical position of the UA and its height above the surface or take-off point;

(iv) the route course measured clockwise from true north and ground speed of the UA;

(v) the geographical position of the remote pilot or, if not available, the take-off point; and

(vi) an indication of the emergency status of the UAS;

(b) reduce the ability of tampering the functionality of the direct remote identification system.

PART 4 — Requirements for a class C3 Unmanned aircraft system

Regulation (EU) 2020/1058

A class C3 UAS bears the following class identification label on the UA:

A class C3 UAS shall comply with the following:

(1) have an MTOM of less than 25 kg, including payload, and have a maximum characteristic dimension of less than 3 m;

(2) have a maximum attainable height above the take-off point limited to 120 m or be equipped with a system that limits the height above the surface or above the take-off point to 120 m or to a value selectable by the remote pilot. If the value is selectable, clear information about the height of the UA above the surface or take-off point during flight shall be provided to the remote pilot;

(3) be safely controllable with regard to stability, manoeuvrability and the command and control link performance, by a remote pilot with adequate competency as defined in Implementing Regulation (EU) 2019/947 and following the manufacturer’s instructions, as necessary under all anticipated operating conditions including following the failure of one or, if appropriate, more systems;

(4) in the case of a tethered UA, have a tensile length of the tether that is less than 50 m and a mechanical strength of no less than:

(a) for heavier-than-air aircraft, 10 times the weight of the aerodyne at maximum mass;

(b) for lighter-than-air aircraft, 4 times the force exerted by the combination of the maximum static thrust and the aerodynamic force of the maximum allowed wind speed in flight;

(5) unless tethered, in case of a loss of the command and control link, have a reliable and predictable method for the UA to recover the command and control link or, if it fails, terminate the flight in a way that reduces the effect on third parties in the air or on the ground;

(6) unless it is a fixed-wing UA, have the indication of the guaranteed A-weighted sound power level LWA determined as per Part 13 affixed on the UA and/or its packaging as per Part 14;

(7) be exclusively powered by electricity;

(8) have a unique serial number compliant with standard ANSI/CTA-2063-A-2019, Small Unmanned Aerial Systems Serial Numbers, 2019;

(9) unless tethered, have a direct remote identification that:

(a) allows the upload of the UAS operator registration number required in accordance with Article 14 of Implementing Regulation (EU) 2019/947 and any additional number provided by the registration system; the system shall perform a consistency check verifying the integrity of the full string provided to the UAS operator at the time of registration; in case of inconsistency, the UAS shall emit an error message to the UAS operator;

(b) ensures, in real time during the whole duration of the flight, the direct periodic broadcast from the UA using an open and documented transmission protocol, in a way that it can be received directly by existing mobile devices within the broadcasting range, of at least the following data:

(i) the UAS operator registration number and the verification code provided by the Member State during the registration process unless the consistency check defined in point (a) is not passed;

(ii) the unique serial number of the UA compliant with point (8);

(iii) the time stamp, the geographical position of the UA and its height above the surface or take-off point;

(iv) the route course measured clockwise from true north and ground speed of the UA;

(v) the geographical position of the remote pilot or, if not available, the take-off point; and

(vi) an indication of the emergency status of the UAS;

(c) reduces the ability of tampering the functionality of the direct remote identification system;

(10) be equipped with a geo-awareness function that provides:

(a) an interface to load and update data containing information on airspace limitations related to UA position and height imposed by the UAS geographical zones, as defined by Article 15 of Implementing Regulation (EU) 2019/947, which ensures that the process of loading or updating of this data does not degrade its integrity and validity;

(b) a warning alert to the remote pilot when a potential breach of airspace limitations is detected; and

(c) information to the remote pilot on the UA’s status as well as a warning alert when its positioning or navigation systems cannot ensure the proper functioning of the geo‑awareness function;

(11) if the UA has a function that limits its access to certain airspace areas or volumes, this function shall operate in such a manner that it interacts smoothly with the flight control system of the UA without adversely affecting flight safety; in addition, clear information shall be provided to the remote pilot when this function prevents the UA from entering these airspace areas or volumes;

(12) unless tethered, be equipped with a command and control link protected against unauthorised access to the command and control functions;

(13) provide the remote pilot with clear warning when the battery of the UA or its command unit reaches a low level such that the remote pilot has sufficient time to safely land the UA;

(14) be equipped:

(a) with lights for the purpose of controllability of the UA; and

(b) with at least one green flashing light for the purpose of conspicuity of the UA at night to allow a person on the ground to distinguish the UA from a manned aircraft;

(15) be placed on the market with manufacturer’s instructions providing:

(a) the characteristics of the UA including but not limited to the:

— class of the UA;

— UA mass (with a description of the reference configuration) and the maximum take-off mass (MTOM);

— general characteristics of allowed payloads in terms of mass, dimensions, interfaces with the UA and other possible restrictions;

— equipment and software to control the UA remotely;

— the procedures to upload the UAS operator registration number into the remote identification system;

— reference of the transmission protocol used for the direct remote identification system emission;

— sound power level;

— description of the behaviour of the UA in case of a loss of the command and control link, and the method to recover command and control link of the UA.

(b) clear operational instructions;

(c) the procedure to upload the airspace limitations into the geo-awareness function;

(d) maintenance instructions;

(e) troubleshooting procedures;

(f) operational limitations (including but not limited to meteorological conditions and day/night operations); and

(g) appropriate description of all the risks related to UAS operations;

(16) include an information notice published by EASA providing the applicable limitations and obligations, in accordance with Implementing Regulation (EU) 2019/947;

(17) if equipped with a network remote identification system it shall:

(a) ensure, in real time during the whole duration of the flight, the transmission from the UA using an open and documented transmission protocol, in a way that it can be received through a network, of at least the following data:

- the UAS operator registration number and the verification code provided by the Member State of registration during the registration process unless the consistency check defined in point 9(a) is not passed;

- the unique serial number of the UA compliant with point (8);

- the time stamp, the geographical position of the UA and its height above the surface or take-off point;

- the route course measured clockwise from true north and ground speed of the UA;

- the geographical position of the remote pilot or, if not available, the take-off point; and

- an indication of the emergency status of the UAS;

(b) reduce the ability of tampering the functionality of the direct remote identification system.

PART 5 — Requirements for a class C4 Unmanned aircraft system

Regulation (EU) 2020/1058

A class C4 UAS bears the following label on the UA in a visible manner:

A class C4 UAS shall comply with the following:

(1) have an MTOM of less than 25 kg, including payload;

(2) be safely controllable and manoeuvrable by a remote pilot following the manufacturer’s instructions, as necessary under all anticipated operating conditions including following the failure of one or, if appropriate, more systems;

(3) not be capable of automatic control modes except for flight stabilisation assistance with no direct effect on the trajectory and lost link assistance provided that a pre-determined fixed position of the flight controls in case of lost link is available;

(4) be placed on the market with manufacturer’s instructions providing:

(a) the characteristics of the UA including but not limited to the:

— class of the UA

— UA mass (with a description of the reference configuration) and the maximum take-off mass (MTOM);

— general characteristics of allowed payloads in terms of mass, dimensions, interfaces with the UA and other possible restrictions;

— equipment and software to control the UA remotely; and

— a description of the behaviour of the UA in case of a loss of the command and control link;

(b) clear operational instructions;

(c) maintenance instructions;

(d) troubleshooting procedures;

(e) operational limitations (including but not limited to meteorological conditions and day/night operations); and

(f) appropriate description of all the risks related to UAS operations;

(5) include an information notice published by EASA providing the applicable limitations and obligations, in accordance with Implementing Regulation (EU) 2019/947.

PART 6 — Requirements for a direct remote identification add-on

Regulation (EU) 2020/1058

A direct remote identification add-on shall comply with the following:

(1) allow the upload of the UAS operator registration number required in accordance with Article 14 of Implementing Regulation (EU) 2019/947 and any additional number provided by the registration system; the system shall perform a consistency check verifying the integrity of the full string provided to the UAS operator at the time of registration; in case of inconsistency, the system shall emit an error message to the UAS operator;

(2) have a unique serial number compliant with standard ANSI/CTA-2063-A-2019, Small Unmanned Aerial Systems Serial Numbers, 2019, affixed to the add-on and its packaging or its manufacturer’s instructions in a legible manner;

(3) ensure, in real time during the whole duration of the flight, the direct periodic broadcast from the UA using an open and documented transmission protocol, in a way that it can be received directly by existing mobile devices within the broadcasting range, of at least the following data:

(i) the UAS operator registration number and the verification code provided by the Member State of registration during the registration process unless the consistency check defined in point (a) is not passed;

(ii) the unique serial number of the add-on compliant with point (2);

(iii) the time stamp, the geographical position of the UA and its height above the surface or take-off point;

(iv) the route course measured clockwise from true north and ground speed of the UA; and

(v) the geographical position of the remote pilot or, if not available, the take-off point;

(4) reduce the ability of tampering the functionality of the direct remote identification system; and

(5) be placed on the market with manufacturer’s instructions providing the reference of the transmission protocol used for the direct remote identification emission and the instruction to:

(a) install the module on the UA; and

(b) upload the UAS operator registration number.

PART 7 — Conformity assessment Module A — Internal production control

Regulation (EU) 2020/1058

1. Internal production control is the conformity assessment procedure whereby the manufacturer fulfils the obligations set out in points 2, 3 and 4 of this Part, and ensures and declares on their sole responsibility that the products concerned satisfy the requirements set out in Parts 1, 5, 6, 16 or 17 which apply to them.

2. Technical documentation

The manufacturer shall develop the technical documentation in accordance with Article 17 of this Regulation.

3. Manufacturing

The manufacturer shall take all measures necessary so that the manufacturing process and its monitoring ensure compliance of the manufactured product with the technical documentation referred to in point 2 of this Part and with the requirements set out in Parts 1, 5, 6, 16 or 17 which apply to them.

4. CE marking and EU declaration of conformity

(1) In accordance with Articles 15 and 16 of this Regulation, the manufacturer shall affix the CE marking and, when applicable, the UA class identification label, to each individual product that satisfies the applicable requirements set out in Parts 1, 5, 6, 16 or 17 which apply to them.

(2) The manufacturer shall draw up a written EU declaration of conformity for each product model and keep it together with the technical documentation at the disposal of the national authorities for 10 years after the product has been placed on the market. The EU declaration of conformity shall clearly identify the product for which it has been drawn up.

A copy of the EU declaration of conformity shall be made available to the relevant authorities upon request.

5. Authorised representative

The manufacturers’ obligations set out in point 4 may be fulfilled by an authorised representative, on their behalf and under their responsibility, provided that they are specified in the mandate.

PART 8 — Conformity assessment Modules B and C — EU-type examination and conformity to type based on internal production control

Regulation (EU) 2020/1058

When reference is made to this Part, the conformity assessment procedure shall follow Modules B (EU-type examination) and C (Conformity to type based on internal production control) of this Part.

Module B

EU-type examination

1. EU-type examination is the part of a conformity assessment procedure in which a notified body examines the technical design of the product and verifies and attests that the technical design of the product meets the applicable requirements set out in Parts 1 to 6, 16 and 17.

2. EU-type examination shall be carried out by an assessment of the adequacy of the technical design of the product through examination of the technical documentation and supporting evidence referred to in point 3, plus examination of specimens, representative of the production envisaged, of one or more critical parts of the product (combination of production type and design type).

3. The manufacturer shall lodge an application for EU-type examination with a single notified body of his choice.

The application shall include:

(1) the name and address of the manufacturer and, if the application is lodged by the authorised representative, his name and address as well;

(2) a written declaration that the same application has not been lodged with any other notified body;

(3) the technical documentation; the technical documentation shall make it possible to assess the product’s conformity with the applicable requirements of this Regulation and shall include an adequate analysis and assessment of the risk(s); the technical documentation shall contain, wherever applicable, the elements set out in Article 17 of this Regulation;

(4) the specimens representative of the production envisaged; the notified body may request further specimens if needed for carrying out the test programme;

(5) the supporting evidence for the adequacy of the technical design solution; this supporting evidence shall mention any documents that have been used, in particular where the relevant harmonised standards and/or technical specifications have not been applied or have not been applied in full; the supporting evidence shall include, where necessary, the results of tests carried out in accordance with other relevant technical specifications by the appropriate laboratory of the manufacturer or by another testing laboratory on his behalf and under his responsibility.

4. The notified body shall:

For the product:

(1) examine the technical documentation and supporting evidence to assess the adequacy of the product’s technical design.

For the specimen(s):

(2) verify that the specimen(s) has (have) been manufactured in conformity with the technical documentation, and identify the elements which have been designed in accordance with the applicable provisions of the relevant harmonised standards and/or technical specifications, as well as the elements which have been designed without applying the relevant provisions of those standards;

(3) carry out appropriate examinations and tests, or have them carried out, to check whether, where the manufacturer has chosen to apply the solutions in the relevant harmonised standards and/or technical specifications, these have been applied correctly;

(4) carry out appropriate examinations and tests, or have them carried out, to check whether, where the solutions in the relevant harmonised standards and/or technical specifications have not been applied, the solutions adopted by the manufacturer meet the corresponding essential requirements of the legislative instrument;

(5) agree with the manufacturer on a location where the examinations and tests will be carried out.

5. The notified body shall draw up an evaluation report that records the activities undertaken in accordance with point 4 and their outcomes. Without prejudice to its obligations as provided in point 8, the notified body shall release the content of this report, in full or in part, only with the agreement of the manufacturer.

6. Where the type meets the requirements of this Regulation, the notified body shall issue an EU‑type examination certificate to the manufacturer. This certificate shall contain the name and address of the manufacturer, the conclusions of the examination, the relevant aspects of the requirements covered by the examination, the conditions (if any) for its validity, and the data necessary for the identification of the approved type. The certificate may have one or more annexes attached to it.

The EU certificate and its annexes shall contain all relevant information to allow the conformity of manufactured products with the examined type to be evaluated and to allow for in service control.

Where the type does not satisfy the applicable requirements of this Regulation, the notified body shall refuse to issue an EU-type examination certificate and shall inform the applicant accordingly, giving detailed reasons for its refusal.

7. The notified body shall keep itself apprised of any changes in the generally acknowledged state of the art which indicates that the approved type may no longer comply with the applicable requirements of this Regulation, and shall determine whether such changes require further investigation. If so, the notified body shall inform the manufacturer accordingly.

The manufacturer shall inform the notified body that holds the technical documentation relating to the EU-type examination certificate of all modifications to the approved type that may affect the product’s conformity with the essential requirements of this Regulation or the conditions for the certificate’s validity. Such modifications shall require additional approval and attached to the original EU-type examination certificate.

8. Each notified body shall inform its notifying authority concerning the EU-type examination certificates and/or any additions thereto which it has issued or withdrawn, and shall, periodically or upon request, make available to its notifying authority the list of certificates and/or any additions thereto refused, suspended or otherwise restricted.

Each notified body shall inform the other notified bodies concerning the EU-type examination certificates and/or any additions thereto which it has refused, withdrawn, suspended or otherwise restricted, and, upon request, concerning the certificates and/or additions thereto which it has issued.

The Commission, the Member States and the other notified bodies may, on request, obtain a copy of the EU-type examination certificates and/or additions thereto. On a reasoned request, the Commission and the Member States may obtain a copy of the technical documentation and the results of the examinations carried out by the notified body.

The notified body shall keep a copy of the EU-type examination certificate, its annexes and additions, as well as the technical file including the documentation submitted by the manufacturer for 10 years after the product has been assessed or until the validity of the certificate expires.

9. The manufacturer shall keep a copy of the EU-type examination certificate, its annexes and additions together with the technical documentation at the disposal of the national authorities for 10 years after the product has been placed on the market.

10. The manufacturer’s authorised representative may lodge the application referred to in point 3 and fulfil the obligations set out in points 7 and 9, provided that they are specified in the mandate.

Module C

Conformity to type based on internal production control

1. Conformity to type based on internal production control is the part of a conformity assessment procedure whereby the manufacturer fulfils the obligations laid down in points 2 and 3, and ensures and declares that the products concerned are in conformity with the type described in the EU-type examination certificate and satisfy the applicable requirements of this Regulation.

2. Manufacturing

The manufacturer shall take all measures necessary so that the manufacturing process and its monitoring ensure conformity of the manufactured product with the approved type described in the EU-type examination certificate and with the applicable requirements set out in Parts 1 to 6, 16 and 17.

3. CE marking and EU declaration of conformity

(1) The manufacturer shall affix the CE marking and, when relevant, the UA class identification label in accordance with Articles 15 and 16 of this Regulation to each product that is in conformity with the type described in the EU-type examination certificate and satisfies the applicable requirements set out in Parts 1 to 6, 16 and 17.

(2) The manufacturer shall draw up a written EU declaration of conformity for each product type and keep it at the disposal of the national authorities for 10 years after the product has been placed on the market. The EU declaration of conformity shall clearly identify the product type for which it has been drawn up.

A copy of the EU declaration of conformity shall be made available to the relevant authorities upon request.

4. Authorised representative

The manufacturer’s obligations set out in point 3 may be fulfilled by their authorised representative, on their behalf and under their responsibility, provided that this is specified in the mandate.

PART 9 — Conformity assessment Module H — Conformity based on full quality assurance

Regulation (EU) 2020/1058

1. Conformity based on full quality assurance is the conformity assessment procedure whereby manufacturers fulfil the obligations set out in paragraphs 2 and 5, and ensure and declare on their sole responsibility that the product concerned satisfies the applicable requirements set out in Parts 1 to 6, 16 and 17.

2. Manufacturing

The manufacturer shall operate an approved quality system for design, manufacture, final inspection and testing of the product concerned as specified in point 3 and shall be subject to surveillance as specified in point 4.

3. Quality system

(1) The manufacturer shall lodge an application for the assessment of his quality system with the notified body of their choice, for the product concerned.

The application shall include:

(a) the name and address of the manufacturer and, if the application is lodged by the authorised representative, their name and address as well;

(b) the technical documentation for each type of product intended to be manufactured, containing the elements set out in Part 10 where applicable;

(c) the documentation concerning the quality system;

(d) a written declaration stating that the same application has not been lodged with any other notified body.

(2) The quality system shall ensure compliance of the product with the requirements of this Regulation.

All the elements, requirements and provisions adopted by the manufacturer shall be documented in a systematic and orderly manner in the form of written policies, procedures and instructions. This quality system documentation shall permit a consistent interpretation of the quality programmes, plans, manuals and records.

The documentation shall, in particular, contain an adequate description of:

(a) the quality objectives and the organisational structure, responsibilities and powers of the management with regard to product design and quality;

(b) the technical design specifications, including standards, that will be applied and, where the relevant harmonised standards will not be applied in full, the means that will be used to ensure that the requirements of this Regulation are met;

(c) the design control and design verification techniques, processes and systematic actions that will be used when designing the products pertaining to the product type covered;

(d) the corresponding manufacturing, quality control and quality assurance techniques, processes and systematic actions that will be used;

(e) the examinations and tests that will be carried out before, during and after manufacture, and the frequency with which they will be carried out;

(f) the quality records, such as inspection reports and test data, calibration data, reports concerning the qualifications or approvals of the personnel concerned, etc.;

(g) the means of monitoring the achievement of the required design and product quality and the effective operation of the quality system.

(3) The notified body shall assess the quality system to determine whether it satisfies the requirements referred to in point 3(2).

It shall presume conformity with those requirements in respect of elements of the quality system that comply with the corresponding specifications of the relevant harmonised standard.

In addition to experience in quality management systems, the auditing team shall have at least one member experienced as an assessor in the relevant product field and product technology concerned, and knowledge of the applicable requirements of this Regulation. The audit shall include an assessment visit on the manufacturer’s premises. The auditing team shall review the technical documentation referred to in point 3(1)(b) to verify the manufacturer’s ability to identify the applicable requirements of this Regulation and to carry out the necessary examinations with a view to ensuring the product’s compliance with these requirements.

The manufacturer or his authorised representative shall be notified of the decision.

The notification shall contain the conclusions of the audit and the reasoned assessment decision.

(4) The manufacturer shall undertake to fulfil the obligations arising out of the quality system as approved and to maintain it so that it remains adequate and efficient.

The manufacturer shall keep the notified body that has approved the quality system informed of any intended change to the quality system.

(5) The notified body shall evaluate any proposed changes and decide whether the modified quality system will continue to satisfy the requirements referred to in point 3(2) or whether a reassessment is necessary.

The notified body shall notify the manufacturer of its decision. The notification shall contain the conclusions of the examination and the reasoned assessment decision.

4. Surveillance under the responsibility of the notified body

(1) The purpose of surveillance is to make sure that the manufacturer duly fulfils the obligations arising out of the approved quality system.

(2) The manufacturer shall, for assessment purposes, allow the notified body access to the design, manufacture, inspection, testing and storage sites, and shall provide it with all necessary information, in particular:

(a) the quality system documentation;

(b) the quality records as provided for by the design part of the quality system, such as results of analyses, calculations, tests, etc.;

(c) the quality records as provided for by the manufacturing part of the quality system, such as inspection reports and test data, calibration data, reports concerning the qualifications of the personnel, etc.

(3) The notified body shall carry out periodic audits to make sure that the manufacturer maintains and applies the quality system and shall provide the manufacturer with an audit report.

(4) In addition, the notified body may pay unexpected visits to the manufacturer. During such visits, the notified body may, if necessary, carry out UA or UAS tests, or have them carried out, in order to check the proper functioning of the quality system. It shall provide the manufacturer with a visit report and, if tests have been carried out, with a test report.

5. CE marking and EU declaration of conformity

(1) The manufacturer shall affix the CE marking and, when relevant, the UAS class identification label in accordance with Articles 15 and 16 of this Regulation and, under the responsibility of the notified body referred to in point 3(1) of this Part, the latter’s identification number to each individual product that satisfies the applicable requirements of this Regulation.

(2) The manufacturer shall draw up a written EU declaration of conformity for each product type and keep it at the disposal of the national authorities for 10 years after the product has been placed on the market. The EU declaration of conformity shall identify the product type for which it has been drawn up.

A copy of the EU declaration of conformity shall be made available to the relevant authorities upon request.

6. The manufacturer shall, for a period ending 10 years after the product has been placed on the market, keep at the disposal of the national authorities:

(1) the technical documentation referred to in point 3(1);

(2) the documentation concerning the quality system referred to in point 3(1);

(3) the change referred to in point 3(5), as approved;

(4) the decisions and reports of the notified body referred to in points 3(5), 4(3) and 4(4).

7. Each notified body shall inform its notifying authority of the quality system approvals issued or withdrawn, and shall, periodically or upon request, make available to its notifying authority the list of the quality system approvals it has refused, suspended or otherwise restricted.

Each notified body shall inform the other notified bodies of the quality system approvals which it has refused, suspended or withdrawn, and, upon request, of quality system approvals which it has issued.

8. Authorised representative

The manufacturer’s obligations set out in points 3(1), 3(5), 5 and 6 may be fulfilled by their authorised representative, on their behalf and under their responsibility, provided that this is specified in the mandate.

PART 10 — Contents of the technical documentation

Regulation (EU) 2020/1058

The manufacturer shall establish the technical documentation. The documentation shall make it possible to assess the product’s conformity to the applicable requirements.

The technical documentation shall, wherever applicable, contain at least the following elements:

1. a complete description of the product including:

(a) photographs or illustrations showing its external features, markings and internal layout;

(b) the versions of any software or firmware involved in compliance with the requirements set by this Regulation;

(c) manufacturer’s and installation instructions;

2. conceptual design and manufacturing drawings and schemes of components, sub-assemblies, circuits and other relevant similar elements;

3. descriptions and explanations necessary for the understanding of those drawings and schemes and the operation of the product;

4. a list of the harmonised standards applied in full or in part, the references of which have been published in the Official Journal of the European Union, and, where those harmonised standards have not been applied, descriptions of the solutions adopted to meet the essential requirements set out in Article 4, including a list of other relevant technical specifications applied. In the event of partly applied harmonised standards, the technical documentation shall specify the parts which have been applied;

5. copy of the EU declaration of conformity;

6. where the conformity assessment module in Part 8 has been applied, copy of the EU-type examination certificate and its annexes as delivered by the notified body involved;

7. results of design calculations made, examinations carried out, and other relevant similar elements;

8. test reports;

9. copies of the documents that the manufacturer has submitted to the notified body if any involved;

10. the supporting evidence for the adequacy of the technical design solution. This supporting evidence shall mention any documents that have been used, in particular where the relevant harmonised standards and/or technical specifications have not been applied in full. The supporting evidence shall include, where necessary, the results of tests carried out by the appropriate laboratory of the manufacturer, or by another testing laboratory on his behalf and under his responsibility;

11. addresses of places of manufacture and storage.

PART 11 — EU declaration of conformity

Regulation (EU) 2020/1058

1. The product (type, batch and serial number).

2. Name and address of the manufacturer or his authorised representative.

3. This declaration of conformity is issued under the sole responsibility of the manufacturer. [in case of a kit of accessories, the manufacturer of the kit may indicate that this certificates relies on the certificate of the UAS which the kit ensures the conversion.]

4. Object of the declaration [identification of the product allowing traceability; it may include a colour image of sufficient resolution where necessary for the identification of the products; in case of a kit of accessories, indicate the type of UAS to which the kit ensures the conversion].

5. The object of the declaration described above is of class … [include for UAS the class number as defined by Parts 1 to 5, 16 and 17 of this Annex; for a kit of accessories, indicate the class into which the UAS is converted].

6. The guaranteed sound power level for this UAS equipment is … dB(A) [for non fixed-wing UAS classes 1 to 3 only]

7. The object of the declaration described above is in conformity with the relevant Union harmonisation legislation:

— [include the reference to this Regulation and the Annex relevant to the class of the product];

— or other Union harmonisation legislation where applicable.

8. References to the relevant harmonised standards used or references to the other technical specifications in relation to which conformity is declared. References must be listed with their identification number and version and, where applicable, date of issue.

9. Where applicable, the notified body … [name, number] … performed … [description of intervention] … and issued the EU-type examination certificate.

10. Where applicable, a description of accessories and components, including software, which allow the unmanned aircraft or unmanned aircraft system to operate as intended and covered by the EU declaration of conformity.

11. Additional information:

Signed for and on behalf of: …

[place and date of issue]:

[name, function] [signature]:

PART 12 — Simplified EU declaration of conformity

Regulation (EU) 2020/1058

The simplified EU declaration of conformity referred to in Article 14(3) shall be provided as follows:

— [Name of manufacturer] hereby declares that the UAS [identification of the UAS: type or serial number] is of class … … [for UAS include the class number of the product as defined in Parts 1 to 5, 16 and 17 of this Annex; for a kit of accessories, indicate the class into which the UAS is converted] and has a guaranteed sound power level of … dB(A) [for non fixed-wing UAS classes 1, 2, 3, 5 and 6 only]

— and in compliance with Regulations … [list all the Regulations that the product complies with].

— The full EU declaration of conformity is accessible at the following website: [website address]

Regulation (EU) 2020/1058

This Part lays down the methods of measurement of airborne noise that shall be used for the determination of the measured A-weighted sound power levels of UA classes 1, 2, 3, 5 and 6.

It lays down the basic noise emission standard and detailed test code for measuring the sound pressure level on a measurement surface enveloping the source and for calculating the sound power level produced by the source.

1. BASIC NOISE EMISSION STANDARD

For the determination of the A-weighted sound power level LWA of UA, the basic noise emission standards EN ISO 3744:2010 will be used subject to the following supplements:

2. INSTALLATION AND MOUNTING CONDITIONS

Test area:

The UA will be maintained above one reflecting (acoustically hard) plane. The UA shall be located at a sufficient distance from any reflecting wall or ceiling or any reflecting object so that the requirements given in Annex A of EN ISO 3744:2010 are satisfied on the measurement surface.

Sound measurement surface and microphone array:

The UA will be completely enclosed in a hemispherical measurement surface as per § 7.2.3 of EN ISO 3744:2010.

The number and position of the microphones is defined by Annex F of EN ISO 3744:2010.

The measurement surface shall have its origin at the point O lying in the ground plane directly below the UA.

3. OPERATING CONDITIONS DURING TEST

The noise tests shall be carried out with the UA’s rotors operating at a speed corresponding to the hovering of the UA under MTOM.

If the UA is placed on the market with accessories that can be fitted to it, it will be tested with and without these accessories in all possible UA configurations.

4. CALCULATION OF SURFACE TIME-AVERAGED SOUND PRESSURE LEVEL

The A-weighted surface time-averaged sound pressure level shall be determined at least three times for each UA configuration. If at least two of the determined values do not differ by more than 1 dB, further measurements will not be necessary; otherwise the measurements shall be continued until two values differing by no more than 1 dB are obtained. The surface time‑averaged sound pressure level to be used for calculating the sound power level of a UA configuration is the arithmetic mean of the two highest values that do not differ by more than 1 dB.

5. INFORMATION TO BE REPORTED

The report shall contain the technical data necessary to identify the source under test as well as the noise test code and the acoustical data.

The A-weighted sound power level value to be reported is the highest value of the different UA configurations tested rounded to the nearest whole number (less than 0,5 use the lower number; greater than or equal to 0,5 use the higher number).

PART 14 — Indication of the guaranteed sound power level

Regulation (EU) 2020/1058

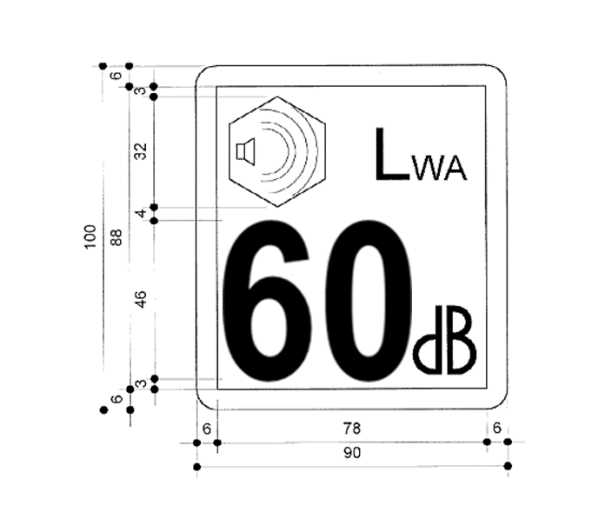

The indication of the guaranteed sound power level must consist of the single number of the guaranteed sound power in dB, the sign LWA and a pictogram taking the following form:

If the indication is reduced according to the size of the equipment the proportions given in the above drawing must be respected. However, the vertical dimension of the indication should, if possible, not be less than 20 mm.

PART 15 — Maximum sound power level per class of UA (including transition periods)

Regulation (EU) 2020/1058

|

UA class |

MTOM m in gram |

Maximum sound power level LWA in dB |

||

|

as from entry into force |

as from 2 years after entry into force |

as from 4 years after entry into force |

||

|

C1 and C2 |

m < 900 |

85 |

83 |

81 |

|

C2 |

900 ≤ m < 4 000 |

85 + 18,5 lg |

83 + 18,5 lg |

81 + 18,5 lg |

Where ‘lg’ is the base 10 logarithm.

PART 16 — Requirements for a class C5 unmanned aircraft system and C5 accessories

Regulation (EU) 2020/1058

A class C5 UAS bears the following class identification label on the UA:

A class C5 UAS shall comply with the requirements defined in Part 4, except those defined in paragraphs (2) and (10) of Part 4.

In addition, it shall comply with the following requirements:

(1) be an aircraft other than a fixed-wing aircraft unless tethered;

(2) if it is equipped with a geo-awareness function, comply with paragraph (10) of Part 4;

(3) during flight, provide the remote pilot with clear and concise information on the height of the UA above the surface or take-off point;

(4) unless tethered, be equipped with a low-speed mode selectable by the remote pilot and limiting the ground speed to not more than 5 m/s;

(5) unless tethered, provide means for the remote pilot to terminate the flight of the UA, which shall:

(a) be reliable, predictable and independent from the automatic flight control and guidance system; this applies also to the activation of this means;

(b) force the descent of the UA and prevent its powered horizontal displacement; and

(c) include means to reduce the effect of the UA impact dynamics;

(6) unless tethered, provide the remote pilot with means to continuously monitor the quality of the command and control link and receive an alert when it is likely that the link is going to be lost or degraded to the extent of compromising the safe conduct of the operation, and another alert when the link is lost; and

(7) in addition to the information indicated in point (15)(a) of Part 4, include in the manufacturer’s instructions a description of the means to terminate the flight required in point (5).

(8) A class C5 UAS may consist in a class C3 UAS fitted with an accessories kit that ensures the conversion of the UAS C3 into a class C5 UAS. In this case, the class C5 label shall be affixed on all the accessories.

An accessories kit may only ensure conversion of a class C3 UAS that complies with point (1) and provides the necessary interfaces to the accessories.

The accessories kit shall not include changes to the software of the class C3 UAS.

The accessories kit shall be designed, and each accessory shall be identified, to ensure a complete and correct installation by a UAS operator on a class C3 UAS following the instructions provided by the manufacturer of the accessories kit.

The accessories kit may be placed on the market independently from the class C3 UAS for which they ensure the conversion. In this case, the manufacturer of the accessories kit shall place on the market a single conversion kit that shall:

(1) not alter the compliance of the class C3 UAS with the requirements of Part 4;

(2) ensure compliance of the UAS fitted with the accessories kit with all additional requirements defined in this Part with the exception of point (3) above; and

(3) be accompanied by manufacturer’s instructions providing:

(i) the list of all class C3 UAS to which the kit can be applied; and

(ii) instructions on how to install and operate the accessories kit.

PART 17 — Requirements for a class C6 unmanned aircraft system

Regulation (EU) 2020/1058

A class C6 UAS bears the following class identification label on the UA:

A class C6 UAS shall comply with the requirements defined in Part 4, except those defined in paragraphs (2), (7) and (10).

In addition, it shall comply with the following requirements:

- have a maximum ground speed in level flight of not more than 50 m/s;

- if it is equipped with a geo-awareness function, comply with paragraph (10) of Part 4;

- during flight, provide the remote pilot with clear and concise information on the geographical position of the UA, its speed and its height above the surface or take-off point;

- provide means to prevent the UA from breaching the horizontal and vertical limits of a programmable operational volume;

- provide means for the remote pilot to terminate the flight of the UA, which shall:

(a) be reliable, predictable, independent from the automatic flight control and guidance system and independent from the means to prevent the UA from breaching the horizontal and vertical limits as required in point (4); this applies also to the activation of this means; and

(b) force the descent of the UA and prevent its powered horizontal displacement;

- provide means to programme the UA trajectory;

- provide the remote pilot with means to continuously monitor the quality of the command and control link and receive an alert when it is likely that the link is going to be lost or degraded to the extent of compromising the safe conduct of the operation, and another alert when the link is lost; and

- in addition to the information indicated in point (15)(a) of Part 4, include in the manufacturer’s instructions:

(a) a description of the means to terminate the flight required in point (5);

(b) a description of the means to prevent the UA from breaching the horizontal and vertical limits of the operational volume and the size of the contingency volume needed to accommodate position assessment error, reaction time and correction manoeuvre span; and

(c) the distance most likely to be travelled by the UA after activation of the means to terminate the flight defined in point (5), to be considered by the UAS operator when defining the ground risk buffer.