Regulation (EU) No 748/2012

This Subpart establishes the procedure for issuing type-certificates for products and restricted type-certificates for aircraft, and establishes the rights and obligations of the applicants for, and holders of, those certificates.

Regulation (EU) No 748/2012

Any natural or legal person that has demonstrated, or is in the process of demonstrating, its capability in accordance with point 21.A.14 shall be eligible as an applicant for a type‑certificate or a restricted type-certificate under the conditions laid down in this Subpart.

21.A.14 Demonstration of capability

Regulation (EU) 2019/897

(a) An applicant for a type-certificate or restricted type-certificate shall demonstrate its capability by holding a design organisation approval, issued by the Agency in accordance with Subpart J.

(b) By way of derogation from point (a), as an alternative procedure to demonstrate its capability, an applicant may seek the agreement of the Agency for the use of procedures setting out the specific design practices, resources and sequence of activities necessary to comply with this Annex I (Part 21), when the product is one of the following:

1. an ELA2 aircraft;

2. an engine or propeller installed in ELA2 aircraft;

3. a piston engine;

4. a fixed or adjustable pitch propeller.

(c) By way of derogation from point (a), an applicant may demonstrate its capability by obtaining the Agency's acceptance of its certification programme established in accordance with point 21.A.15(b), where the product to be certified is:

1. an ELA1 aircraft; or

2. an engine or propeller installed in ELA1 aircraft.

AMC1 21.A.14(b) Demonstration of capability

ED Decision 2021/001/R

ALTERNATIVE PROCEDURES FOR THE DEMONSTRATION OF DESIGN CAPABILITY

The availability of procedures that state the specific design practices, resources and sequence of activities is an acceptable means to demonstrate design capability in the cases described in points 21.A.14(b), 21.A.112B(b) or 21.A.432B(b). This concept is that the implementation, in the context of specific projects, of the procedures required for a Subpart J DOA, will ensure that the applicant performs the relevant activities, but without the requirements on the organisation itself. The setting up of those procedures may be seen as a starting phase for a design organization to develop into a Subpart J DOA by the addition of the missing elements.

1. Scope

1.1 A manual of procedures should be provided that sets out the specific design practices, resources and the sequence of activities that are relevant for the specific projects, taking the Part 21 requirements into account.

1.2 These procedures should be concise and limited to the information that is needed for the quality and proper control of activities by the applicant/holder, and by EASA.

2. Management of the (supplemental) type-certification process

2.1 Certification programme: see AMC 21.A.15(b) for type certification and AMC 21.A.93(b) for supplemental type certification.

2.2 Compliance demonstration: see GM 21.A.20.

2.3 Reporting: see GM 21.A.20(b).

2.4 Compliance documentation: see AMC 21.A.20(c).

2.5 Declaration of compliance: see GM 21.A.20(d).

3. Management of changes to type certificates, repair designs and production deviations

3.1 Management of changes to a type certificate or supplemental type certificate (hereinafter referred to as ‘changes’), repair designs and production deviations from the approved design data.

The applicant should provide procedures that are acceptable to EASA for the classification and approval of changes (see paragraphs 3.2 and 3.3), repair designs and production deviations from the approved design data.

3.2 Classification

3.2.1 Content

The procedure should address the following points:

— the identification of the product configuration(s) to which the change is to be made,

— the identification of the areas of the product that are changed or affected by the change,

— the identification of any reinvestigations that are necessary (see point 21.A.93(b)(2)), including the identification of the applicable certification specifications or environmental protection requirements and means of compliance,

— changes initiated by subcontractors,

— documents to justify the classification,

— authorised signatories,

— the criteria used for classification must be in compliance with 21.A.91 and the corresponding interpretations.

3.2.2 Identification of changes

The procedure should indicate how the following are identified:

— major changes,

— those minor changes where additional work is necessary to demonstrate compliance with the certification specifications,

— other minor changes that require no further demonstration of compliance.

3.2.3 Considerations of effects of the change

The procedure should show how the effects on airworthiness, operational suitability or environmental protection are analysed, from the very beginning, by reference to the applicable certification specifications.

If no specific certification specifications are applicable to the change, the above review should be carried out at the level of the part or system where the change is integrated and where specific certification specifications are applicable.

3.2.4 Control of changes initiated by subcontractors

The procedure should indicate, directly or by cross reference to written procedures, how changes initiated by subcontractors are controlled.

3.2.5 Documents to justify the classification

All decisions of classification of changes should be documented and approved by EASA. The document may be in the format of meeting notes or a register.

3.2.6 Authorised signatories

The procedure should identify the persons authorised to sign the proposed classification before release to EASA for approval.

3.3 Approval of changes

3.3.1 Content

The procedure should address the following points:

— compliance documentation,

— the internal approval process,

— authorised signatories.

3.3.2 Compliance documentation

For major changes and those minor changes where additional work to demonstrate compliance with the applicable type-certification basis, operational suitability data certification basis, and environmental protection requirements (hereinafter referred to as the ‘certification basis’) is necessary, compliance documentation should be established in accordance with AMC 21.A.20(c).

3.3.3 Approval process

A) For the approval of major changes, a certification programme as defined in AMC 21.A.93(b) must be established.

B) For major changes and those minor changes where additional work to demonstrate compliance with the applicable certification basis is necessary, the procedure should define a document to support the approval process.

This document should include at least:

— identification and a brief description of the change and its classification,

— references to the applicable certification basis,

— reference to the compliance documents,

— effects, if any, on limitations and on the approved design data,

— the name of the authorised signatory.

C) For the other minor changes, the procedure should define a means:

— to identify the change,

— to present the change to EASA for approval.

3.3.4 Authorised signatories

The procedure should identify the persons authorised to sign the change before release to EASA for approval.

3.4 Repair designs and production deviations from the approved design data

A procedure following the principles of paragraphs 3.2 and 3.3 should be established for the classification and approval of repair designs and unintentional deviations from the approved design data occurring in production (concessions or non-conformances). For repair designs, the procedure should be established in accordance with Part 21, Section A, Subpart M and the associated acceptable means of compliance (AMC) or guidance material (GM).

4. Issue of data and information (including instructions) to owners, operators or others required to use the data and information

4.1 General

Data and information include the operational suitability data.

4.2 Data related to changes

The data and information (including instructions) issued by the holder of a design approval (a TC, STC, approval of a change, approval of a repair design) are intended to provide the owners of a product with all the necessary data and information to embody a change or a repair on the product, or to inspect it.

The data and information (including instructions) may be issued in a format of a service bulletin as defined in ATA 100 system, or in structural repair manuals, maintenance manuals, engine and propeller manuals, etc.

The preparation of this data involves design, production and inspection. The three aspects should be properly addressed and a procedure should exist.

4.3 Procedure

The procedure should address the following points:

— Preparation;

— verification of technical consistency with corresponding approved change(s), repair design(s) or approved data, including effectivity, description, effects on airworthiness or operational suitability, especially when limitations are changed;

— verification of the feasibility in practical applications; and

— approval for the release of data and information.

The procedure should include the information (including instructions) prepared by subcontractors or vendors, and declared applicable to its products by the holder of the TC, STC, approval of changes or approval of repair designs.

4.4 Statement

The data and information should include a statement:

— confirming that the documentation has been produced by the design approval holder in accordance with the associated procedures accepted by EASA; and

— containing a reference to EASA approvals of related changes or repairs, when applicable12EASA does not directly approve information or instructions. These are approved as part of the TC, STC, change approval or repair design approval. When stand-alone changes (i.e. not related to a TC change or repair design) to the issued information or instructions (e.g. to take in-service experience into account) are needed, these should be prepared, verified and approved according to the agreed procedures (see above)..

5. Obligations addressed in 21.A.44 (TC holder), 21.A.118A (STC holder) or 21.A.451 (major repair design approval holder)

The applicant for alternative procedures to demonstrate their design capabilities should establish the necessary procedures to show to EASA how it will fulfil the obligations that are required under 21.A.44, 21.A.118A or 21.A.451, as appropriate.

6. Control of design subcontractors

The applicant for alternative procedures to demonstrate their design capabilities should establish the necessary procedures to show to EASA how it will control design subcontractors and ensure the acceptability of the parts or appliances that are designed, or the design tasks that are performed.

GM 21.A.14(b) Eligibility for alternative procedures

ED Decision 2012/020/R

Design organisations approved under Part 21 Section A Subpart J (‘Subpart J DOA’) should be the normal approach for type certification, supplemental type certification, approval of major changes to type design or approval of major repair design, except when agreed otherwise by the Agency in accordance with 21.A.14, 21.A.112B and 21.A.432B.

The acceptance of alternative procedures, as defined in AMC 21.A.14(b), should be limited where the Agency finds it more appropriate for the conduct of type certification, supplemental type certification, approval of changes to type design, approval of repair design.

AMC to 21.A.143, 21.A.243, 21.A.14(b), 21.A.112B(b) and 21.A.432B(b) Flight Test Operations Manual (FTOM)

ED Decision 2017/024/R

1. General

a. Scope: The FTOM covers flight test operations.

The FTOM complexity should be proportionate to the aircraft and the organisation complexity.

b. Format

The FTOM may:

— be included in the Design Organisation Approval (DOA)/Production Organisation Approval (POA)/Alternative Procedure to DOA (APDOA) documents, or

— be a separate manual.

The FTOM may make reference to other documents to cover the contents listed below, e.g. for record-keeping.

c. Use by contractors or sub-contractors:

When flight tests are performed by contractors or sub-contractors, they should comply with the FTOM of the primary organisations, unless they have established an FTOM in compliance with Part-21, the use of which has been agreed between the two organisations.

2. The FTOM should contain the following elements:

a. Exposition (not applicable in the case of APDOA):

If the FTOM is presented as a separate document, it should include a chart indicating the structure of the organisation and, more specifically, the functional links of the people in charge of flight test activities. It should also mention the coordination between all departments affecting flight test, e.g. Design Office, Production and Maintenance, in particular coordination for the establishment and update of a Flight Test Programme.

b. Risk and safety management:

The FTOM should describe the organisation’s policy in relation to risk and safety assessment, mitigation and associated methodologies.

c. Crew members:

According to the flight test category, the FTOM should describe the organisation’s policy on the composition of the crew (including the need to use a Lead Flight Test Engineer (LFTE)) and the competence and currency of its flight test crew members, including procedures for appointing crew members for each specific flight.

All crew members should be listed in the FTOM.

A flight time limitation policy should be established.

d. Carriage of persons other than crew members:

According to the flight test category, the FTOM should describe the organisation’s policy in relation to the presence and safety on-board, of people other than crew members (i.e. with no flying duties).

People other than crew members should not be allowed on board for Category 1 flight tests.

e. Instruments and equipment:

The FTOM should list, depending on the nature of the flight, the specific safety-related instruments and equipment that should be available on the aircraft or carried by people on board.

The FTOM should contain provisions to allow flights to take place in case of defective or missing instruments or equipment.

f. Documents:

The FTOM should list the documents to be produced for flight test, and include (or refer to) the procedures for their issue, update and follow-up to ensure the documents’ configuration control:

(i) documents associated with a Flight Test Programme:

— Flight Order for a given flight, which should include:

— a list of the tests to be performed and associated conditions;

— safety considerations relevant to the flight;

— category of the flight (e.g. Category 1);

— composition of the crew;

— names of persons other than crew members;

— aircraft configuration items relevant to the test to be highlighted to the crew;

— loading of the aircraft;

— reference to approved flight conditions; and

— restrictions relevant to the flight to be highlighted to the crew.

— Flight crew report.

(ii) documentation and information to be carried on the aircraft during flight test;

(iii) record-keeping: the FTOM should describe the policy relative to record-keeping.

g. Permit to fly:

The FTOM should describe the involvement of the flight test organisation or flight test team (as appropriate) in the process for the approval of flight conditions and the issue of permits to fly in accordance with Subpart P.

h. Currency and training:

The FTOM should describe how training for flight test is organised.

Currency of the flight test crew may be ensured either through recent experience or refresher training.

For aircraft for which Appendix XII is applicable, minimum flight experience by year should be:

— for pilots: 50 hours. In addition:

— for pilots with a flight test rating, the 50 hours should include 20 flight test hours in any flight test category.

— for pilots performing a Category 3 flight test, the flight test experience should be expressed in terms of a number of flights leading to the issue of a Certificate of Airworthiness (CofA) (e.g. first flights).

— for pilots performing a Category 4 flight test, the minimum flight test experience should be proportionate to the activity envisaged.

— for LFTEs: 10 flight test hours in any flight test category.

The FTOM should specify the requirements for a refresher training in order to ensure that crew members are sufficiently current to perform the required flight test activity.

A system should be established to record the currency of the flight test crew’s training.

A valid national document (i.e. licence), issued by an EASA Member State under its national regulations and ensuring compliance with the agreed currency requirements, is an acceptable means of compliance to demonstrate currency for a pilot that holds a flight test rating and for an LFTE.

Regulation (EU) 2021/699

(a) An application for a type-certificate or restricted type-certificate shall be made in a form and manner established by the Agency.

(b) An application for a type-certificate or restricted type-certificate shall include, as a minimum, preliminary descriptive data of the product, the intended use of the product and the kind of operations for which certification is requested. In addition, it shall include, or be supplemented after the initial application by, a certification programme for the demonstration of compliance in accordance with point 21.A.20, consisting of:

1. a detailed description of the type design, including all the configurations to be certified;

2. the proposed operating characteristics and limitations;

3. the intended use of the product and the kind of operations for which certification is requested;

4. a proposal for the initial type-certification basis, operational suitability data certification basis and environmental protection requirements, prepared in accordance with the requirements and options specified in points 21.B.80, 21.B.82 and 21.B.85;

5. a proposal for a breakdown of the certification programme into meaningful groups of compliance demonstration activities and data, including a proposal for the means of compliance and related compliance documents;

6. a proposal for the assessment of the meaningful groups of compliance demonstration activities and data, addressing the likelihood of an unidentified non-compliance with the type-certification basis, operational suitability data certification basis or environmental protection requirements and the potential impact of that non-compliance on product safety or environmental protection. The proposed assessment shall take into account at least the elements set out in subpoints (1) to (4) of point 21.B.100(a). Based on this assessment, the application shall include a proposal for the Agency's involvement in the verification of the compliance demonstration activities and data; and

7. a project schedule including major milestones.

(c) After its initial submission to the Agency, the certification programme shall be updated by the applicant when there are changes to the certification project affecting any of the points 1 to 7 of point (b).

(d) An application for a type-certificate or restricted type-certificate for an aircraft shall include, or be supplemented after the initial application by, an application supplement for approval of the operational suitability data.

(e) An application for a type-certificate or restricted type-certificate for a large aeroplane or a large rotorcraft shall be valid for five years and an application for any other type-certificate or restricted type-certificate shall be valid for three years, unless the applicant demonstrates at the time of application that its product requires a longer time period to demonstrate and declare compliance and the Agency agrees to that longer time period.

(f) In the case where a type-certificate or restricted type-certificate has not been issued, or it is evident that it will not be issued, within the time limit provided for in point (e), the applicant may:

1. submit a new application and comply with the type-certification basis, operational suitability data certification basis and environmental protection requirements, as established and notified by the Agency in accordance with points 21.B.80, 21.B.82 and 21.B.85 for the date of the new application; or

2. apply for an extension of the time period provided for in point (e) and propose a new date for the issuance of the type-certificate or restricted type-certificate. In that case, the applicant shall comply with the type-certification basis, operational suitability data certification basis and environmental protection requirements, as established and notified by the Agency in accordance with points 21.B.80, 21.B.82 and 21.B.85 for a date to be selected by the applicant. However, that date shall not precede the new date proposed by the applicant for the issuance of the type-certificate or restricted type-certificate by more than five years for an application for a type-certificate or restricted type-certificate for a large aeroplane or a large rotorcraft, and by more than three years for an application for any other type-certificate or restricted type certificate.

AMC 21.A.15(a) Form and manner

ED Decision 2019/018/R

The applicant should file an application using the web-based ‘EASA Applicant Portal’13 https://ap.easa.europa.eu (changes to the link provided may not be reflected in this document). or the application form for a type certificate or restricted type certificate (FO.CERT.00030)14 http://www.easa.europa.eu/document-library/application-forms/focert00030 (changes to the link provided may not be reflected in this document)., which may be downloaded from the EASA website.

The form should be completed in accordance with the instructions embedded at the bottom of the application form, and sent to EASA by fax, email or regular mail following the information provided on the EASA website15 https://www.easa.europa.eu/document-library/application-forms/certifica… (changes to the link provided may not be reflected in this document)..

AMC 21.A.15(b) Content of the certification programme

ED Decision 2019/018/R

The certification programme is a document that allows the applicant and EASA to manage and control the evolving product type design or OSD, as well as the process of compliance demonstration by the applicant and its verification by EASA when required.

The certification programme may be based on modules that may be updated independently.

The level of detail in the certification programme depends on the complexity of the product and its intended use.

In particular, the following information should typically be expected:

General

— Identification of the relevant personnel who make decisions affecting airworthiness, operational suitability and environmental protection, and who will interface with EASA, unless otherwise identified to EASA (e.g. within the DOA procedures).

— A project schedule including major milestones.

— Subcontracting arrangements for design, operational suitability, environmental protection and/or production as well as design organisation approval (DOA) responsibility sharing.

21.A.15(b)(1) ‘a detailed description of the type design, including all the configurations to be certified’

An overview of the:

— architecture, functions, systems;

— dimensions, design weights, payloads, design speeds;

— engines and power/thrust rating;

— materials and technologies;

— maximum passenger seating capacity, minimum flight and cabin crew;

— cabin configuration aspects;

— options (e.g. weight variants, power/thrust rating variants, optional avionics equipment items, auxiliary power unit (APU) choices, brake options, tire options, floats, skids);

— noise/emissions level; and

— other items, if considered to be more appropriate, that address the specific aeronautical product.

21.A.15(b)(2) ‘proposed operating characteristics and limitations’

— Operating speed limitations.

— Service ceiling, maximum airfield elevation.

— Cabin pressure.

— Limit load factors.

— Number of passengers, minimum crew, payload, range.

— Weight and centre-of-gravity (CG) envelope and fuel loading.

— Performance.

— Environmental envelope.

— Runway surface conditions.

— Other items, if considered to be more appropriate, that address the specific aeronautical product.

21.A.15(b)(3) ‘the intended use of the product and the kind of operations for which certification is requested’

— Category A or B (relevant for CS-27 and CS-29), ditching, take-off and landing on water, emergency floatation equipment.

— Extended overwater operation, high-altitude operation (above 41 000 ft).

— High-airfield operation, steep approach, short take-off and landing, extended-range twin-engine operations (ETOPS), all-weather operations (AWO), visual flight rules (VFR)/instrument flight rules (IFR), reduced vertical separation minimum (RVSM), required navigation performance (RNP) type, increased bank angles, single-pilot operation, flight into known icing conditions.

— Flight in ice crystal icing.

— Engine operations in ice-forming conditions, helicopter hoist operations, operation on unpaved runway, operation on narrow runway.

— Take-off and landing in tailwind.

— Volcanic-ash operation (limitation or operation as per CS 25.1593 and CS-E 1050).

— Design service goal (DSG)/limit of validity targets.

— Fatigue missions (general description of assumptions for flight durations, main phases, and parameters, as appropriate).

— Other items, if considered to be more appropriate, that address the specific aeronautical product.

21.A.15(b)(4) ‘a proposal for the initial type-certification basis, operational suitability data certification basis, where applicable, and environmental protection requirements, considering the requirements and options specified in 21.B.80, 21.B.82 and 21.B.85’

The proposed certification basis should include applicable certification specifications, proposed special conditions, proposed equivalent safety findings, as well as a proposed ‘elect to comply’ and proposed deviations, as applicable.

21.A.15(b)(5) ‘a proposal for a breakdown of the certification programme into meaningful groups of compliance demonstration activities and data, hereinafter referred as “compliance demonstration items” (CDIs), including references to their proposed means of compliance and related compliance documents’

See AMC 21.A.15(b)(5) for the determination of the compliance demonstration items (CDIs).

21.A.15(b)(6) on information relevant for the determination of the level of involvement (LoI)

The applicant should provide sufficient detailed information about the novelty, complexity, and criticality aspects of each proposed CDI.

It is recommended to provide this information at the level of each EASA panel or discipline affected by a proposed CDI. Further interpretative material on the necessary level of details is provided in AMC 21.B.100(a) and 21.A.15(b)(6).

The applicant should provide detailed information about the proposed means of compliance with the applicable requirements identified under 21.A.15(b)(4). The information provided should be sufficient for EASA to determine its (initial) LoI. This should include the following, as far as this information is available at the time of submission to EASA:

— a compliance checklist addressing each requirement, the proposed means of compliance (see Appendix A to AMC 21.A.15(b) below for the relevant codes), and the related compliance document(s);

— identification of industry standards (Society of Automotive Engineers (SAE), American Society for Testing and Materials (ASTM), European Organisation for Civil Aviation Equipment (EUROCAE), AeroSpace and Defence Industries Association of Europe (ASD), etc.), methodology documents, handbooks, technical procedures, technical documents and specifications specified in the type certificate data sheet, certification memoranda, policy statements, guidance material, etc., that should be followed in the demonstration of compliance;

— when the compliance demonstration involves testing, a description of the ground and flight test article(s), test method(s), test location(s), test schedule, test house(s), test conditions (e.g. limit load, ultimate load), as well as of the intent/objective(s) of the testing; and

— when the compliance demonstration involves analyses/calculations, a description/identification of the tools (e.g. name and version/release of the software programs) and methods used, the associated assumptions, limitations and/or conditions, as well as of the intended use and purpose; furthermore, the validation and verification of such tools and methods should be addressed.

For every aspect mentioned above, the applicant should clearly identify whether the demonstration of compliance involves any method (analysis or test) which is novel or unusual for the applicant. This should include any deviations from the published AMC to the relevant CS.

Appendix A to AMC 21.A.15(b) Means of compliance codes

ED Decision 2019/018/R

|

Type of compliance |

Means of compliance |

Associated compliance documents |

|

Engineering evaluation |

MC0: (a) compliance statement (b) reference to design data (c) election of methods, factors, etc. (d) definitions |

(a) Design data (b) Recorded statements |

|

MC1: design review |

(c) Descriptions (d) Drawings |

|

|

MC2: calculation/analysis |

(e) Substantiation reports |

|

|

MC3: safety assessment |

(f) Safety analysis |

|

|

Tests |

MC4: laboratory tests |

(g) Test programmes (h) Test reports (i) Test interpretations |

|

MC5: ground tests on related product(s) |

||

|

MC6: flight tests |

||

|

MC8: simulation |

||

|

Inspection |

MC7: design inspection/audit |

(j) Inspection or audit reports |

|

Equipment qualification |

MC9: equipment qualification |

Note: Equipment qualification is a process that may include all previous means of compliance at equipment level. |

AMC 21.A.15(b)(5) Breakdown of the certification programme into compliance demonstration items (CDIs)

ED Decision 2019/018/R

1. What is a CDI?

A CDI is a meaningful group of compliance demonstration activities and data identified in the certification programme which can be considered in isolation for the purpose of performing the risk assessment that allows EASA to determine its level of involvement (LoI) using a risk-based approach.

The possibility to create this grouping of compliance demonstration activities and data is intended to facilitate the risk assessment. However, there may be cases in which the risk assessment may also be performed at the level of the compliance demonstration activity or data, or at the level of the whole certification project.

The chosen breakdown into CDIs may affect the resulting risk classes (please refer to AMC 21.B.100(a) and 21.A.15(b)(6)), but should not have any effect on the compliance demonstration itself or on EASA’s LoI.

2. The grouping of compliance demonstration activities and data

The compliance demonstration activities and data grouped in a CDI may demonstrate compliance with a requirement, a group of requirements, or even a part of a requirement. In this context, ‘requirement’ means any element of the type-certification basis or operational suitability data (OSD) certification basis as specified in 21.B.80 and 21.B.82, or the environmental protection requirements as specified in 21.B.85.

A CDI may comprise any of the means of compliance listed in Appendix A to AMC 21.A.15(b).

CDIs may be tailored to the scope and size of the project. On simple projects, a CDI may address all the compliance demonstration activities within a given technical area (e.g. avionics, flight, structures, hydromechanical systems, OSD-cabin crew data (CCD), etc.) or of the whole project.

A CDI should not be too large, by combining completely unrelated compliance demonstration activities or data, so that it becomes meaningless, but neither should it be so small that it might not be considered in isolation from some other related compliance demonstration activities or data.

A way of meaningfully grouping compliance demonstration activities and data, for example, is to select some activities and data and group them into a single CDI, as the certification programme must already contain the applicable requirements, the proposed means of compliance for each requirement, as well as the associated compliance documents for each means of compliance.

Another way to meaningfully group the data is to do it at the level of the technically related compliance demonstration activities and data. This may facilitate the assessment of those activities and data against the novelty, complexity, and criticality criteria (see AMC 21.B.100(a) and 21.A.15(b)(6)). The resultant CDI may encompass various means of compliance.

3. Description of CDIs

Each CDI should be sufficiently described in the certification programme, and should detail the following:

— the scope of the CDI; and

— the information on the novelty, complexity, and criticality of the item being certified.

However, in cases where the rationale of the assessment is obvious, it is considered to be sufficient to indicate whether or not a CDI is novel or complex, and whether or not the impact is critical.

Note: Obvious cases are cases for which the classification is straightforward and does not require additional clarifications. In general, applicant explanations/notes regarding the proposed classification should be provided, since this will also facilitate the acceptance of the LOI proposal. Nevertheless, to avoid unnecessary additional effort, these explanations can be omitted if they are obvious.

Additionally, it is recommended to identify the EASA panel(s)/discipline(s) affected by each CDI, as this will support the determination of the novelty, complexity, and criticality, and finally identify the performance of the design organisation approval (DOA) holder.

GM No 1 to 21.A.15(d) Application for the approval of operational suitability data – MMEL for ELA1 and ELA2

ED Decision 2019/018/R

For ELA1 and ELA2, the applicant may develop a list of the required equipment to be included in the TCDS and/or AFM/POH. This list, in combination with the equipment required for the flight by the applicable implementing rules for a given type of operations, establishes the list of equipment that must be operative for all flights. The list of the other installed equipment that may be inoperative constitutes the MMEL.

GM No 2 to 21.A.15(d) Determination of type or variant

ED Decision 2016/007/R

The criteria for the determination whether an aircraft with a new type certificate (TC) is considered a new type or is a variant with reference to another aircraft type from the same TC holder for the purpose of the specific OSD constituent are provided in the applicable certification specifications for maintenance certifying staff data, flight crew data and cabin crew data.

GM No 3 to 21.A.15(d) OSD content

ED Decision 2016/007/R

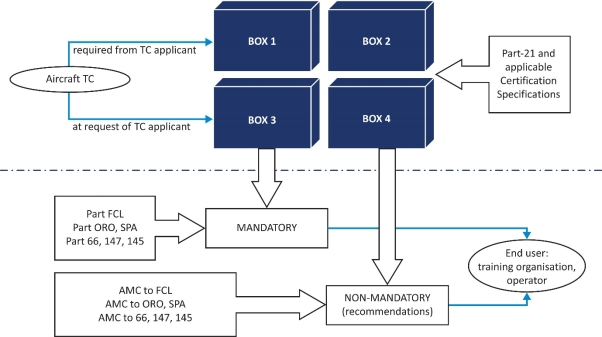

The OSD will typically consist of elements that are required to be included by the TC applicant and elements that can be added at the request of the TC applicant. (See also GM No 4 to 21.A.15(d)).

Both the required elements and the additional elements will have a part that is mandatory to be used by the operator or training organisation (status of rule) and a part which is not mandatory to the operator or training organisation (status of AMC). For illustration of this concept, Figure 1 below is included.

Figure 1: OSD boxes concept

Box 1: required from TC holder; mandatory for end-users.

Box 2: required from TC holder; not mandatory (recommendations) for end-users.

Box 3: at request of TC holder; mandatory for end-users.

The TC applicant may wish to apply for the approval of differences training between variants or types to reduce training, checking or currency requirements for operations of more than one type or variant. This is regarded as an optional element in addition to the required elements of Box 1 and 2.

Box 4: at request of TC holder; not mandatory (recommendations) for end-users.

The exact content of the four boxes in the above figure is determined by the certification specification that is applicable to the specific OSD constituent or the special condition in case of an ‘other type-related operational suitability element’.

The status the data will have on the side of the operator or training organisation should be indicated in the OSD by segregating the data in a section called ‘Mandatory’ and a section called ‘Non-mandatory (recommendations)’.

ED Decision 2021/001/R

SCOPE OF OPERATIONAL SUITABILITY DATA

In the application for the approval of operational suitability data, the TC applicant may apply for the approval of different types of operations. If the aircraft is certified for certain types of operations (e.g. ETOPS, RNP, LVO), the impact on the OSD constituents of 21.A.15(d) should be addressed.

The five defined OSD constituents are listed in paragraph (2)(k) of Article 1 of Regulation (EU) No 748/2012. As explained in GM No 1 to 21.A.15(d), they may not all be applicable to all aircraft types. The content of each OSD constituent is defined in the relevant certification specification (CS) and will be approved under a type certificate (TC), supplemental type certificate (STC) or change to those certificates. As explained in GM No 3 to 21.A.15(d), each OSD constituent can have a part that is mandatory for the end user (operator, training organisation, etc.) and a part that is not mandatory (recommendation) for the end user. However, both the mandatory and the non‑mandatory part together are the OSD constituent. Furthermore, the OSD constituent always includes the element required from the TC/STC applicant, as specified in the CS, and may include additional elements at the request of the TC/STC applicant, but still as defined in the CS.

GM 21.A.15(c) Updates to the certification programme

ED Decision 2019/018/R

Point 21.A.15(b) recognises that the initial submission of the certification programme may not be fully complete, e.g. due to schedule constraints of the design, analysis and testing activities.

Furthermore, even if the initial submission of the certification programme is complete, it may be necessary to amend it throughout the duration of the project.

The certification programme should be updated and resubmitted to EASA. In particular, updates to the following elements should be provided:

— any complementary information that was not included in the initial submission of the certification programme;

— any change in the intended use or kind of operations of the product itself, or of the aircraft on which the product is installed;

— a change in the key characteristics of the product such as but not limited to any declared limits that are intended to be recorded in the type certificate data sheet (TCDS);

— any change in the product design or its characteristics that may affect the criteria used to assess the likelihood of an unidentified non-compliance with the type-certification basis, operational suitability data (OSD) certification basis or the environmental protection requirements, including the potential impact of that non-compliance on product safety or environmental protection, as defined in 21.A.15(b)(6) and 21.B.100(a)(1) to (4);

Note: An update of the DOA dashboard after the first issuance of the certification programme only needs to be considered if there is a significant change in the performance.

— any change to the initial type-certification basis, OSD certification basis or environmental protection requirements, as applicable to the product, regardless whether the change is initiated by EASA or by the applicant;

— any change in the breakdown of the certification programme into compliance demonstration items (CDIs) or in the content of those CDIs;

— any change in the proposed means of compliance, including its/their methodology;

— any change in the structure of compliance documents that may affect the determination of EASA’s level of involvement (LoI), as defined in 21.B.100;

— any relevant change to the design organisation approval (DOA) holder’s personnel (and design organisation (DO) suppliers) who are involved in the project; and

— any changes to the schedule that impact on the EASA LoI.

Following each update to the certification programme as submitted by the applicant, EASA may update the determination of its LoI in accordance with 21.B.100(c).

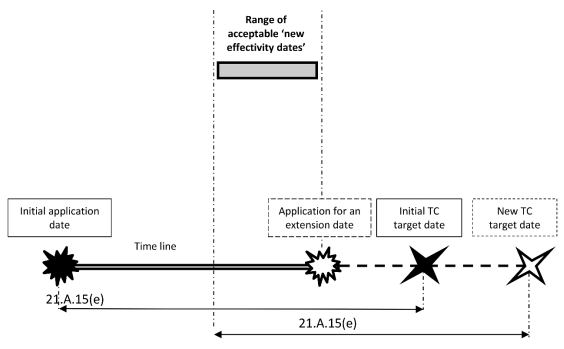

GM 21.A.15(e) and (f) Period of validity for the application for a type certificate (TC) or restricted type certificate (RTC)

ED Decision 2019/018/R

Point 21.A.15(e) establishes a maximum period of validity for an application for a TC or an RTC. During this period, the type-certification basis, operational suitability data (OSD) certification basis, and the environmental protection requirements (hereinafter referred to as the ‘certification basis’), established and notified by EASA in accordance with points 21.B.80, 21.B.82 and 21.B.85, remain effective. However, the period of validity of the certification basis is limited so that the standards notified as part of the certification basis at the time of application do not become outdated.

For various reasons (e.g. development, business, commercial, etc.), the applicant may not be able to complete the certification within the established time limit. In this case, the applicant has the following two options (see 21.A.15(f)(1) and (2)):

1. Submit a new application In this case, EASA establishes and notifies a new certification basis in accordance with points 21.B.80, 21.B.82 and 21.B.85, considering the standards that are available at the date of the new application.

In accordance with point 21.A.15(e), the new application has a maximum period of validity that is equal to the first one, corresponding to the product category. Beyond this period of validity, the applicant may need to choose again between the two options of either submitting a new application or applying for an extension of the initial application.

2. Apply for an extension of the initial application

In this case, the applicant proposes a ‘new target date’ to EASA for the issuance of the certificate, and selects a date that becomes the reference date for the establishment of the certification basis by EASA. For the purposes of this GM, the selected reference date is referred to as the ‘new effectivity date’ of the initial application.

The ‘new effectivity date’ of the initial application may be any date in the past between the following time limits:

— the ‘new target date’ for a TC proposed by the applicant minus the time limit used under 21.A.15(e) (e.g. 5 years for large aeroplanes and large rotorcraft, 3 years for the other products); and

— the date on which the applicant applies for the extension of the initial application.

This calculation is visualised in Figure 1 below:

Figure 1

This ensures that the standards used to establish the certification basis are never older than the ones available at the start of the period of validity required by point 21.A.15(e).

If the applicant is not able to complete the product certification by the new target date, the applicant may choose again between the two options of either submitting a new application or applying for a new extension of the initial application.

21.A.19 Changes requiring a new type-certificate

Regulation (EU) No 748/2012

Any natural or legal person proposing to change a product shall apply for a new type-certificate if the Agency finds that the change in design, power, thrust, or mass is so extensive that a substantially complete investigation of compliance with the applicable type-certification basis is required.

21.A.20 Demonstration of compliance with the type certification basis, operational suitability data certification basis and environmental protection requirements

Regulation (EU) 2019/897

(a) Following the acceptance of the certification programme by the Agency, the applicant shall demonstrate compliance with the type certification basis, operational suitability data certification basis and environmental protection requirements, as established and notified to the applicant by the Agency in accordance with points 21.B.80, 21.B.82, 21.B.85, and shall provide the Agency with the means by which such compliance has been demonstrated.

(b) The applicant shall report to the Agency any difficulty or event encountered during the process of demonstration of compliance that may have an appreciable effect on the risk assessment under point 21.A.15(b)(6) or on the certification programme, or may otherwise necessitate a change to the level of involvement of the Agency previously notified to the applicant in accordance with point 21.B.100(c).

(c) The applicant shall record justifications of compliance within the compliance documents as referred to in the certification programme.

(d) After completion of all demonstrations of compliance in accordance with the certification programme, including any inspections and tests in accordance with point 21.A.33, and after all flight tests in accordance with point 21.A.35, the applicant shall declare that:

1. it has demonstrated compliance with the type-certification basis, operational suitability data certification basis and environmental protection requirements, as established and notified by the Agency, following the certification programme as accepted by the Agency; and

2. no feature or characteristic has been identified that may make the product unsafe for the uses for which certification is requested.

(e) The applicant shall submit to the Agency the declaration of compliance provided for in point (d). Where the applicant holds an appropriate design organisation approval, the declaration of compliance shall be made in accordance with Subpart J and submitted to the Agency.

GM 21.A.20 Compliance demonstration process

ED Decision 2019/018/R

Point 21.A.20 applies to the compliance demonstration process for a type certificate (TC) (or a restricted type certificate (RTC)) and, by cross references to Part 21 Subpart D and E, to compliance demonstration processes for major changes to a TC (see point 21.A.97(b)(3)) and an STC (see point 21.A.115(b)(4)).

Applicants for a TC (or an RTC) should apply point 21.A.20 in full. Applicants for a major change to a TC (or an STC) are required (see points 21.A.97(b)(3) and 21.A.115(b)(4)) to apply point 21.A.20 as applicable to the change.

‘As applicable to the change’ means that:

— the certification programme to be followed is the one prepared for the major change or STC in accordance with point 21.A.93, as accepted by EASA; and

— the certification basis (consisting of the type-certification basis, operational suitability data (OSD) certification basis, and the environmental protection requirements) is the one established by EASA in accordance with point 21.A.101 and notified to the applicant in accordance with point 21.B.105 (for a major change to a TC) or point 21.B.109 (for an STC).

Point 21.A.20 also applies to major changes to a TC or an STC approved by design organisation approval (DOA) holders under their privilege as per point 21.A.263(c)(8) or (9) (see also points 21.A.97(b)(3) and 21.A.115(b)(4)). As in this case there is no application and no EASA involvement, point 21.A.20 should be applied with the following adaptions:

— the certification programme to be followed, including the certification basis and the detailed means of compliance, should be almost identical to the one accepted by EASA for a major change or an STC when approved for the scope of the privilege as per point 21.A.263(c)(8) or (9); it may differ in some aspects (e.g. the detailed description of the changes), but it should be shown to remain in the frame of the corresponding justification document; and

— the means by which such compliance has been demonstrated (see point 21.A.20(a)) and the final declaration of compliance (see point 21.A.20(e)) should be kept on record and submitted to EASA only if EASA requests them during its DOA continued surveillance process.

GM 21.A.20(b) Reporting on the compliance demonstration process

ED Decision 2019/018/R

The applicant should report to EASA any unexpected difficulty or event encountered during the compliance demonstration that invalidates or appreciably affects the assumptions previously made, for example:

— an increase in the severity of the consequences of a certain condition (e.g. failure mode) of the product;

— significantly reduced margin(s) for the ‘pass–fail’ criteria of the compliance demonstration;

— changes to the test sequences and conditions that are not in line with the certification specifications or guidance;

— an unusual interpretation of the results of the compliance demonstration; and

— any significant failure or finding resulting from the tests performed as per points 21.A.33 or 21.A.35.

The applicant should also evaluate whether the unexpected difficulty or event encountered will impact on the certification programme and, if necessary, amend it as per point 21.A.15(c).

AMC 21.A.20(c) Compliance documentation

ED Decision 2019/018/R

1. Compliance documentation comprises one or more test or inspection programmes/plans, reports, drawings, design data, specifications, calculations, analyses, etc., and provides a record of the means by which compliance with the applicable type-certification basis, the operational suitability certification basis and environmental protection requirements is demonstrated.

2. Each compliance document should normally contain:

— the reference of the certification specifications, special conditions or environmental protection requirements addressed by the document;

— substantiation data demonstrating compliance (except test or inspection programmes/plans);

— a statement by the applicant declaring that the document provides the proof of compliance for which it has been created; and

— the appropriate authorised signature.

3. Each compliance document should be unequivocally identified by its reference and issue date. The various issues of a document should be controlled and comply with point 21.A.55.

ED Decision 2019/018/R

All compliance demonstrations in accordance with the certification programme, including all the inspections and tests in accordance with point 21.A.33 and all flight tests in accordance with point 21.A.35, should be completed before the issuance of the final statement of compliance required by point 21.A.20(d).

If so agreed by EASA, some compliance documentation may be produced after the issuance of the final statement of compliance required by 21.A.20(d).

‘No feature or characteristics’ in point 21.A.20(d)2 means the following: while every effort is made to address in the applicable certification basis all the risks to product safety or to the environment that may be caused by the product, experience shows that safety-related events may occur with products in service, even though compliance with the certification basis is fully demonstrated. One of the reasons may be that some existing risks are not properly addressed in the certification basis. Therefore, the applicant has to declare that they have not identified any such features or characteristics.

Point 21.A.20 also applies by reference to minor changes, in which case the risk to product safety or to environmental protection is quite low. Nevertheless, minor changes should not be approved if either the applicant/design organisation approval (DOA) holder approving minor changes under their privileges, or EASA, is aware of a feature or characteristic that may make the product unsafe for the uses for which certification is requested.

21.A.21 Requirements for the issuance of a type certificate or restricted type certificate

Regulation (EU) 2019/897

(a) In order to be issued a product type certificate or, when the aircraft does not meet the essential requirements of Annex II to Regulation (EU) 2018/1139 an aircraft restricted type certificate, the applicant shall:

1. demonstrate its capability in accordance with point 21.A.14;

2. comply with point 21.A.20;

3. demonstrate that the engine and propeller, if installed in the aircraft:

(A) have a type-certificate issued or determined in accordance with this Regulation; or

(B) have been demonstrated to be in compliance with the aircraft type-certification basis established and the environmental protection requirements designated and notified by the Agency as necessary to ensure the safe flight of the aircraft.

(b) By derogation from point (a)(2), at the applicant's request included in the declaration referred to in point 21.A.20(d), the applicant is entitled to have the aircraft type-certificate or restricted type-certificate issued before the applicant has demonstrated compliance with the operational suitability data certification basis, provided that the applicant demonstrates such compliance before the date at which those data are to be actually used.

GM 21.A.21(a)(3)(i) Clarification of the term ‘determined’

ED Decision 2021/011/R

A type certificate ‘determined’ in accordance with Part 21 means a type certificate, or a document that allows the issuance of a certificate of airworthiness, issued before 28 September 2003 by a Member State complying with Article 3(1)(a) of Regulation (EU) No 748/2012.

GM 21.A.21(b), 21.A.95(c), 21.A.97(c), 21.A.115(c), 21.B.103(b), 21.B.107(b) and 21.B.111(b) Approval of operational suitability data (OSD)

ED Decision 2019/018/R

It is acknowledged that it may not always be possible to have the OSD available on the date of the issue of the (restricted) type certificate ((R)TC), change approval or supplemental type certificate (STC). The derogation provided by 21.A.21(b), 21.A.95(c), 21.A.97(c), 21.A.115(c), 21.B.103(b), 21.B.107(b) and 21.B.111(b) is intended for that case. The (R)TC, change approval or STC can be issued before compliance with the OSD certification basis has been demonstrated.

However, the OSD needs to be approved before the data is used by a training organisation for the purpose of obtaining a European Union (EU) licence, rating or attestation, or by an EU operator. This is normally done before the entry into service of the first aircraft by an EU operator but it could also be done later for some of the OSD constituents, such as the definition of the scope of validation source data to support the objective qualification of a simulator, which should only be available when a simulator has to be qualified.

The derogation provided in points 21.A.97(c), 21.A.115(c), 21.B.103(b), 21.B.107(b), and 21.B.111(b) is applicable to all major changes to a TC, so it is also applicable to minor design changes when triggering a major master minimum equipment list (MMEL) change, as well as to changes in which at least one of the OSD constituent changes is major.

Regulation (EU) 2019/897

(a) The type design shall consist of:

1. the drawings and specifications, and a listing of those drawings and specifications, necessary to define the configuration and the design features of the product shown to comply with the applicable type-certification basis and environmental protection requirements;

2. information on materials and processes and on methods of manufacture and assembly of the product necessary to ensure the conformity of the product;

3. an approved airworthiness limitations section of the instructions for continued airworthiness as defined by the applicable certification specifications; and

4. any other data allowing by comparison the determination of the airworthiness and, if relevant, the environmental characteristics of later products of the same type.

(b) Each type design shall be adequately identified.

Regulation (EU) 2019/897

(a) (Reserved)

(b) Before each test is undertaken during the demonstration of compliance required by point 21.A.20, the applicant shall have verified:

1. for the test specimen, that:

(i) the materials and processes adequately conform to the specifications for the proposed type design;

(ii) the parts of the products adequately conform to the drawings in the proposed type design; and

(iii) the manufacturing processes, construction and assembly adequately conform to those specified in the proposed type design; and

2. for the test and measuring equipment to be used for the test, that those are adequate for the test and appropriately calibrated.

(c) On the basis of the verifications carried out in accordance with point (b), the applicant shall issue a statement of conformity listing any potential non-conformity, together with a justification that this will not affect the test results, and shall allow the Agency to make an inspection it considers necessary to check the validity of that statement.

(d) The applicant shall allow the Agency to:

1. review any data and information related to the demonstration of compliance; and

2. witness or carry out any test or inspection conducted for the purpose of the demonstration of compliance.

(e) For all the tests and inspections witnessed or carried out by the Agency in accordance with point (d)(2):

1. the applicant shall submit to the Agency a statement of conformity provided for in point (c); and

2. no change that affects the validity of the statement of conformity shall be made to the test specimen, or the test and measuring equipment, between the time the statement of conformity provided for in point (c) was issued and the time the test specimen is presented to the Agency for test.

AMC 21.A.33 Inspections and tests

ED Decision 2019/018/R

Use of the term ‘applicant’: point 21.A.33 is applicable to type certification, major changes, major repairs and supplemental type certificates (STCs), and through reference in point 21.A.604 to ETSO for auxiliary power units (APUs). Despite using the word ‘applicant’, it is also applicable to major changes, major repairs and STCs approved under DOA privileges (see point 21.A.263(c)(5), (8) or (9)).

Proposed type design: this term defines the type design (or the portion of the type design) as it is determined at the time when the inspection or test is undertaken.

Statement of conformity: for each certification inspection or test, the statement of conformity issued in accordance with point 21.A.33(c) must address the conformity of the test specimen (see point 21.A.33(b)(1)) as well as of the test equipment and measuring equipment (see point 21.A.33(b)(2)).

Conformity of the test specimen: the statement of conformity required by point 21.A.33(c) is intended to ensure that the manufactured test specimen adequately represents the proposed type design. Possible types of non-conformity may be the following:

— Non-conformity between the design of the test specimen and the proposed type design at the time of the test. These are typically identified in the early stage of the test planning, and should be addressed as early as possible (e.g. in the test plan). There may be several reasons for such a non-conformity: to account for interfaces with the test equipment, to conservatively cover several or future design configurations, etc.

— Non-conformity between the manufactured test specimen and the design of the test specimen. Such a non-conformity may be the result of the manufacturing of the test specimen.

While it is convenient to define any possible non-conformity in (a) as early as possible, the applicant does not need to make the distinction between the two types of non-conformity above as long as they are explicitly addressed and justified in the statement of conformity or by cross reference to the test plan or other documents.

Type certification is typically an iterative process in which the design is under continuous evolution. If the type design evolves after the time of the inspection or test, then the final type design should be checked against the proposed type design (as it was at the time of the inspection or test), and the differences (if any) should be analysed to ensure that the inspection or test results are representative of the final configuration. However, such changes made to the type design may lead to the invalidation of the inspection or test results and a need to repeat the inspection or test. It is recommended that the design organisation should have a thorough configuration management process to track the evolving type design.

Conformity of test and measuring equipment: the configuration of the test and measuring equipment should be defined in the test plan and include the following:

— definition/design of the test equipment (relevant tools, mechanical parts, electronic components used to execute the test); and

— definition of the measuring equipment:

— type/model of sensors, together with their technical characteristics;

— position and orientation of exciters and sensors; and

— electronic measuring equipment (in some cases, this may also include the acquisition and post-processing of data).

The configuration of the test and measuring equipment should be defined and controlled through certification test plans and supporting documentation, according to the design assurance system, if applicable. The test plan should also include the following elements:

— the test cases, methods, and procedures for test execution;

— the pass–fail criteria; and

— pre-, during- and post-test inspections.

The statement of conformity of point 21.A.33(c) should confirm that the test and measuring equipment conform to its purpose, and that the sensors and measuring system are appropriately calibrated. Any non-conformity should be assessed, and it should be justified that it will not compromise the test purpose and results. This can be done either in the statement of conformity or by cross reference to other documents (test minutes of meetings, test notes, etc.).

Use of the term ‘adequate’: the test specimen, as well as the test and measuring equipment, are considered to be ‘adequate’ as long as the test execution on the manufactured test specimen (including any non-conformity) and the use of the installed test set-up does not compromise the test purpose and results (for example, by providing better performance than the proposed type design, or masking any potential failure mode or behaviour).

Changes that affect the validity of the statement of conformity (see point 21.A.33(e)(2)): if changes need to be introduced to the test specimen or to the test and measurement equipment after the statement of conformity is issued (and before the test is undertaken), the statement of conformity must be updated. The updated statement of conformity must be made available to EASA before the test if EASA has informed the applicant that it will witness or carry out the tests.

Development versus certification tests: sometimes, tests of specimens that conform to a preliminary design, but are not intended for certification (known as development tests), are performed as part of a risk control strategy and to develop knowledge of a subject. Problems and failures found during development are part of the process of increasing the understanding of the design, including its failure modes and the potential for optimisation. Such development tests do not need to meet the requirements of point 21.A.33.

Any planned test event should be classified in advance as either a development test or a certification test. Tests that support the compliance demonstration should be classified as certification tests.

Nevertheless, if agreed by EASA, it is acceptable for a development test to finally form part of the compliance demonstration, and it may be declared afterwards to be a certification test as long as it meets the requirements of point 21.A.33. For this reason, it is important to keep the configuration of such tests under the control of the design organisation.

In addition to this, the level of involvement (LoI) notified by EASA as per 21.B.100(c) should be taken into account: if EASA has determined that it will witness or conduct a certain test, this test may need to be repeated so that EASA can witness or conduct the test.

If the test specimen used for a certification test has already undergone a series of previous tests that may affect or ultimately invalidate its acceptance as required by point 21.A.33(b), this aspect should be considered when issuing the statement of conformity required by point 21.A.33(c), and specific analyses or inspections may be required to support such a statement.

Because of the above aspects, EASA advises applicants to inform EASA if they intend to conduct a campaign of development tests that may eventually be used as certification tests.

Availability of compliance data (see point 21.A.33(d)(1)): data and information requested from the applicant for review should be made available in a reliable and efficient way that is agreed between the applicant and EASA.

Point 21.A.33(d)(1) refers to any data or information related to compliance data; the scope of that requirement is therefore not limited to inspections and tests. In particular, point 21.A.33(d)(1) is not limited to data and information related to compliance demonstration items (CDIs) in which EASA is involved.

GM 21.A.33(d) Inspections and tests

ED Decision 2019/018/R

The applicant should inform EASA sufficiently in advance about the execution of inspections and tests that are used for compliance demonstration purposes unless EASA has explicitly excluded these inspections and tests from its involvement according to 21.B.100.

Additionally, the applicant may propose to EASA to perform or witness flight or other tests of particular aspects of the product during its development and before the type design is fully defined. However, before EASA performs or witnesses any flight test, the applicant should have performed these tests already before EASA and should ensure that no features of the product preclude the safe conduct of the evaluation requested.

EASA may require any such tests to be repeated once the type design is fully defined to ensure that subsequent changes have not adversely affected the conclusions from any earlier evaluation.

A statement of conformity as per point 21.A.33(c) is also required for the above tests.

Regulation (EU) No 748/2012

(a) Flight testing for the purpose of obtaining a type-certificate shall be conducted in accordance with conditions for such flight testing specified by the Agency.

(b) The applicant shall make all flight tests that the Agency finds necessary:

1. to determine compliance with the applicable type-certification basis and environmental protection requirements; and

2. to determine whether there is reasonable assurance that the aircraft, its parts and appliances are reliable and function properly for aircraft to be certificated under this Annex I (Part 21), except for,

(i) sailplanes and powered sailplanes,

(ii) balloons and airships defined in ELA1 or ELA2,

(iii) aeroplanes of 2 722 kg or less maximum take-off mass (MTOM).

(c) (Reserved)

(d) (Reserved)

(e) (Reserved)

(f) The flight tests prescribed in point (b)(2) shall include:

1. for aircraft incorporating turbine engines of a type not previously used in a type-certificated aircraft, at least 300 hours of operation with a full complement of engines that conform to a type-certificate; and

2. for all other aircraft, at least 150 hours of operation.

ED Decision 2012/020/R

Detailed material on flight testing is included in the applicable CS and GM.

GM 21.A.35(b)(2) Objective and Content of Function and Reliability Testing

ED Decision 2012/020/R

1. OBJECTIVE

The objective of this testing is to expose the aircraft to the variety of uses, including training, that are likely to occur when in routine service to provide an assurance that it performs its intended functions to the standard required for certification and should continue to do so in service.

2. CONTENT OF FUNCTION AND RELIABILITY TESTING

The testing should cover both routine operations and some simulation of abnormal conditions. The details of the programme should be agreed with the Agency prior to commencement of testing.

It may be possible to combine this testing with any required to demonstrate compliance with the applicable CS. This will be agreed on a case-by-case basis with the Agency.

Where possible, testing conditions should be defined with the co-operation of an operator.

A substantial proportion of the flying should be on a single aircraft. The flying should be carried out to a continuous schedule on an aircraft that is very close to the final type design, operated as though it were in service and should include a range of representative ambient operating conditions and airfields.

GM 21.A.35(f)(1) Flying Time for Function and Reliability Testing

ED Decision 2012/020/R

All flying carried out with engines and associated systems not significantly different from the final type-certificate standard may count towards the 300 hours airframe flight time required by 21.A.35(f)(1). At least 150 of the 300 flying hours should be conducted on a dedicated production configured aircraft. The requirement for 300 hours relevant flight time whenever a new turbine engine is incorporated applies regardless of whether the airframe/engine combination is subject to a new type-certificate or is to be certificated as a change or supplement to an existing type-certificate.

GM 21.A.35(f)(2) Flying Time for Function and Reliability Testing

ED Decision 2012/020/R

All flying carried out on an aircraft not significantly different from the final type design may count towards the 150 hours airframe flight time required by 21.A.35(f)(2).

Regulation (EU) 2021/699

The type-certificate and restricted type-certificate shall include the type design, the operating limitations, the instructions for continued airworthiness, the type-certificate data sheet for airworthiness and emissions, the applicable type-certification basis and environmental protection requirements with which the Agency records compliance, and any other conditions or limitations prescribed for the product in the applicable certification specifications and environmental protection requirements. The aircraft type-certificate and restricted type-certificate shall include in addition the applicable operational suitability data certification basis, the operational suitability data and the type-certificate data sheet for noise. The aircraft type-certificate and restricted type-certificate data sheet shall include the record of CO2 emissions compliance and the engine type-certificate data sheet shall include the record of exhaust emissions compliance.

21.A.44 Obligations of the holder

Regulation (EU) 2022/201

Each holder of a type-certificate or restricted type-certificate shall:

(a) undertake the obligations laid down in points 21.A.3A, 21.A.3B, 21.A.4, 21.A.5, 21.A.6, 21.A.7, 21.A.9, 21.A.62 and 21.A.65, and, for this purpose, shall continue to meet the qualification requirements for eligibility under point 21.A.13; and

(b) specify the marking in accordance with Subpart Q.

Regulation (EU) 2022/201

The transfer of a type-certificate or a restricted type-certificate or an ETSO authorisation for an auxiliary power unit may only be made to a natural or legal person that is able to undertake the obligations laid down in point 21.A.44, and, for this purpose, has demonstrated its capability in accordance with point 21.A.14.

21.A.51 Duration and continued validity

Regulation (EU) No 748/2012

(a) A type-certificate and restricted type-certificate shall be issued for an unlimited duration. They shall remain valid subject to:

1. the holder remaining in compliance with this Annex 1 (Part 21); and

2. the certificate not being surrendered or revoked under the applicable administrative procedures established by the Agency.

(b) Upon surrender or revocation, the type-certificate and restricted type-certificate shall be returned to the Agency.

21.A.62 Availability of operational suitability data

Regulation (EU) No 69/2014

The holder of the type-certificate or restricted type-certificate shall make available:

(a) at least one set of complete operational suitability data prepared in accordance with the applicable operational suitability certification basis, to all known EU operators of the aircraft, before the operational suitability data must be used by a training organisation or an EU operator; and

(b) any change to the operational suitability data to all known EU operators of the aircraft; and

(c) on request, the relevant data referred to in points (a) and (b) above, to:

1. the competent authority responsible for verifying conformity with one or more elements of this set of operational suitability data; and

2. any person required to comply with one or more elements of this set of operational suitability data.

GM to 21.A.62, 21.A.108 and 21.A.120B Availability of Operational Suitability Data

ED Decision 2014/007/R

(a) When making data available, the holder of the design approval (TC, change approval, STC) should take into account the applicable security laws.

(b) When making data available, the holder of the design approval can impose conditions addressing the intellectual property nature of the data.

21.A.65 Continuing structural integrity for aeroplanes structures

Regulation (EU) 2021/699

The holder of the type-certificate or restricted type-certificate for a large aeroplane shall ensure that the continuing structural integrity programme remains valid throughout the operational life of the aeroplane, taking into account service experience and current operations.

AMC1 21.A.65 Continuing structural integrity programme for aeroplane structures

ED Decision 2021/007/R

Type-certificate (TC) or restricted type-certificate (RTC) holders for large aeroplanes should implement a process to ensure the continuing structural integrity of the aeroplane’s structures following its entry into service.

For those large aeroplanes subject to point 26.300 of Part-26, compliance with point 21.A.65 of Part 21 is demonstrated by complying with point 26.305 of Part-26 within the timescale indicated therein.

For other large aeroplanes, the process should be established considering the points described below:

(a) Overall objectives

The objective of point 21.A.65 of Part 21 is to ensure that the continuing structural integrity programme remains valid throughout the operational life of the aeroplane and will preclude unsafe levels of fatigue cracking and other forms of structural degradation.

The intent is for (R)TC holders for large aeroplanes to monitor the continued validity of the assumptions upon which the ICA related to the aeroplane structures are based, and to ensure that unsafe levels of fatigue cracking or other structural deterioration will be precluded in service.

To achieve this objective, (R)TC holders are expected to work together with aircraft operators.

The process should apply to all structures whose failure could contribute to a catastrophic failure, and it is not limited to metallic structures or fatigue cracking, but should also encompass composite and hybrid structures and associated failure modes.

(b) Description of the process to maintain the validity of the continuing structural integrity programme

The process to maintain the validity of the continuing structural integrity programme is either continuous with each service finding, or is a regular review following several findings, or a combination of both. It should include the following:

(1) a plan to audit and report to EASA the effectiveness of the continuing structural integrity programme, including the continuing validity of the assumptions upon which it is based, prior to reaching any significant point in the life of the aeroplane;

(2) criteria for summarising findings of fatigue, environmental or accidental damage and their causes, and recording them in a way that allows any potential interaction to be evaluated;

(3) criteria to assess and record the relevance of each potential contributing factor to the finding, including operational usage, fatigue load spectra, environmental conditions, material properties, manufacturing processes and the fatigue- and damage-tolerance analytical methods of analysis and their implementation;

(4) criteria for establishing and revising sampling programmes to supplement the inspections and other procedures established in compliance with the applicable fatigue- and damage‑tolerance requirements;

(5) criteria for establishing when structures should be modified, or the inspection programme revised, in the light of in-service damage findings;

(6) sunset criteria: the extent to which the above elements of the process require definition may be tailored to the size of the fleet and its expected useful remaining life.